Doing more with less: the cement sector using waste as a resource

Co-processing of waste materials for the purpose of energy or resource recovery has been an important topic in the cement industry for a long time. Publications and articles have been published to explain the rationale for co-processing. In this article, the World Business Council for Sustainable Development’s (WBCSD) Cement Sustainability Initiative (CSI) aims at explaining both how and why cement companies should consider co-processing, based on the two CSI documents: “Guidelines for Co-Processing Fuels and Raw Materials in Cement Manufacturing” and “Waste Management Solutions by the Cement Industry”, the latter first published in 2014.

1 Responsible use of fuels and raw materials

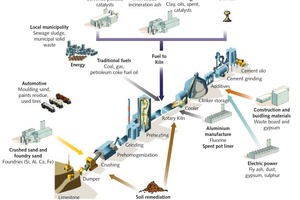

Acknowledging cement production is an energy and resource intensive activity, the sector makes the efficient use of fuels and raw materials a priority. Co-processing of waste as a replacement of conventional fuels is playing an ever more important role as modern society faces the challenge of better waste management. Responsible producers see the importance of using less resources to deliver the same quality and quantity of product.

Non-recyclable wastes and/or by-products from domestic, industrial, or agricultural sources can be used as fuels,...