Drive system conversions pay off for building materials producers

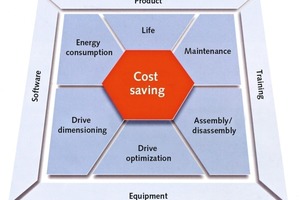

As Andreas Lenz, Brammer’s Marketing Manager for Germany, notes: “Investments in conversion are only worthwhile if the modified machines subsequently generate benefits in the form of longer service lives, shorter setting-up times and greater energy efficiency.” Finding precisely the right product on the market, with exactly the properties and performance the company needs – and at a rational price – can often involve a large amount of time and effort, he affirms. “Mistakes can easily occur, particularly where procurement, energy-efficiency and spares stocking are concerned,” adds Lenz.

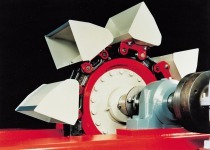

Here, a dependable MRO partner can ensure a trouble-free conversion process. Brammer has a proven track record as an expert in conversion and optimization and also possesses the necessary product and process competence, as the following example demonstrates: a company producing building materials commissioned the Karlsruhe experts for the conversion of a hammer mill from V-belt to toothed-belt drive. The twin-motor machine was incurring speed losses of 244 rpm during its working phase – almost 17 %, at a rated drive speed of 1430 rpm. It was necessary to fit new V-belts on average every six months. The new system would be required to achieve improvements in service lives, energy costs and setting-up times.

Brammer noted the data for the old drive system and extra-polated them with the assistance of a specialist. It turned out the motor, previously driven by eight V-belts, could be replaced by a model employing a much more efficient toothed belt and a corresponding toothed drive pulley.

The new system meets the customer’s requirements to the full: operating times of three years between maintenance reduce stockholding costs, since it is no longer necessary to re-equip the drive system five times each year. In addition, the new system’s 149 kg lower weight permits easier installation and shorter setting-up times. Above all, the elimination of speed losses achieves annual energy savings amounting to around 20 000 €. This alone means that the building materials producer will have saved some 60 000 € by the next scheduled maintenance shutdown in three years time – with improved machine productivity as an important extra benefit.