Egypt’s cement industry prepares

for the move to solid fuels

The introduction to the seminar program provided some general information about the cement industry in Egypt, with its total of 49 cement plants with 76 kiln lines and a production of about 150 000 t/d. The latest available figures indicate an expected increase in demand of around 30 % by 2018, which corresponds to a production of 80 million tons of cement annually.

The first item on the agenda was the present supply of fuels to the Egyptian cement industry. Dr. Ibrahim Ismail pointed out the most recent data collected by the government regarding the imports. Currently only natural gas and oil are used. This would have been perfect as long as these raw materials were available cheap on site. “However, since Egypt has to rely on expensive energy imports, this is no longer so easy,” said Dr. Ismail. A first step therefore would be the transition to solid fuels such as lignite or hard coal. For this purpose, there are still some difficulties to be overcome, for example the logistics such as port facilities for imported coal and transporting facilities as well as the appropriate treatment technology for the coal and grinding mills.

As a second step, Dr. Ismail recommended the addition of secondary fuels such as residual or agricultural waste. The former would require investments beyond 100 million €, and in the second group there would be a calculated risk imputed for the available amount, since large amounts of agricultural waste would be used further. The use of sewage sludge Ismail saw as a problem due to its content of heavy metals.

Regarding coal and the transition to this energy source, Egypt certainly needs 10 million t/a, Dr. Ismail said. Potential suppliers were Russia, Turkey, Ukraine and South Africa. He also took into account petcoke from domestic refineries or from Europe. Overall, there were plenty of opportunities to meet a future demand for cement in Egypt at reasonable prices, despite high prices for primary fuels, said Ismail in conclusion. To that he listed a number of measures that need to be made by the Egyptian Government, but also by private investors.

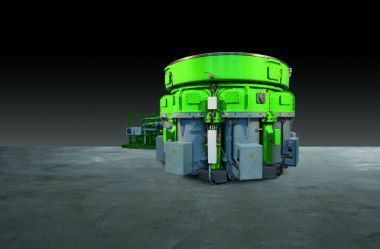

Gerhard Salewski and Thomas Fahrland informed the seminar participants in their presentations on plants for milling coal and petroleum coke that could be installed in the foreseeable future due to the use of alternative fuels in the existing Egyptian cement plants. Here one must always take into account, Fahrland said, that a modern grinding technology is a closed system that can execute several steps simultaneously – grinding, drying and separating – which, in turn reduces costs. Salewski illuminated the structure of the corresponding logistics chain for imported coal from ship transport, harbour facilities, grinding up to the transportation to the individual cement plants.

About the function and operation of the Loesche VRM with technology and construction as a modular system and the corresponding safety technology informed Bernhard Schröder.

Wilfred Zieri (A TEC) spoke about the influence on the pyroprocess by using solid fuels and possible technical solutions. Andreas Moser (Greco) gave information about an appropriate burner technology and the special requirements for kilns and calciner burners using coal or petcoke.

As a very interested audience the participants took the opportunity to discuss all technical and environmental aspects and details with the teams of Loesche, A TEC and Greco, making the event a very successful one.