Electronic warning systems increase operational safety

Whether in mining or in industrial use, conveyor belts are subjected to heavy loads in many applications. Years of stress and sharp-edged objects can leave their mark on conveyor belts. ContiTech from Hanover, Germany has developed innovative electronic conveyor belt warning and inspection systems to detect damage at an early stage and to determine the state of conveyor belts. The warning systems can cope with the extreme use requirements while guaranteeing a high degree of safety for the entire conveying system.

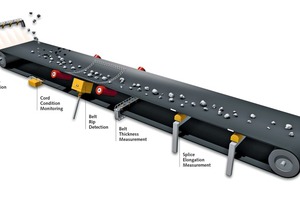

Under the name CONTI® PROTECT, the warning systems prevent conveyor belt systems from major damage, thereby making an important contribution to increasing operational safety, thanks to a reduction in damage-related idle times. CONTI® PROTECT Splice Elongation Measurement is designed to monitor large conveyor belt systems, and detects irregularities in the splice length with the help of magnetic markings. “Monitoring the splice increases the operational safety of conveyor systems with ever lower safety factors and ever higher conveyor belt strengths,” says Arndt Bunzel, application engineer of the Mining World segment at the ContiTech Conveyor Belt Group.

CONTI® PROTECT Belt Rip Detection detects longitudinal rips in the conveyor belt early on with the help of vulcanized conductor loops. With improved conductor loops and a lower electromagnetic susceptibility to faults, the belt warning system prevents incorrect messages and thus expensive system standstills. Moreover, online support is also available: On request, ContiTech experts can log into the system and check and optimize processes via remote maintenance.

CONTI® INSPECT systems supply data that can be used to make reliable prognoses regarding the remaining service life of the conveyor belt and to estimate the investment costs more accurately. This makes an important contribution toward reducing operating costs. The mobile CONTI® INSPECT Belt Thickness Measurement system measures the thickness of the conveyor belt across the entire length of the belt. Surface damage can be detected at an early stage with the CONTI® INSPECT Continuous Surface Inspection system. The most modern scan technologies are used to inspect the conveyor belt surface and to gain a detailed image of the belt surface and quality. CONTI® INSPECT belt warning systems can be used during ongoing system operation. System holding times for painstaking inspections can therefore be avoided, and the outlay for conveyor belt inspections reduced. CONTI® INSPECT Cord Monitoring monitors the steel cord of the carcass with a magnetic-inductive procedure and allows its condition to be assessed precisely.

In the development of its electronic warning systems, ContiTech leverages synergies from the company and builds on the expertise of the Continental Automotive Group, which develops and produces cutting-edge electronic systems for the passenger and commercial vehicle industry. Thanks to this collaboration, innovative solutions for enhanced safety in conveyor belt systems are created.

//www.contitech.de" target="_blank" >www.contitech.de:www.contitech.de