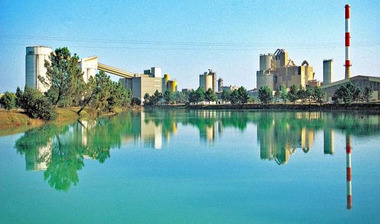

FLSmidth cuts up to 20% CO2 with one of the world’s largest clay calcination solutions

A new clay calcination project in Ghana marks a key milestone in the green transition of cement production. FLSmidth will deliver equipment to replace cement clinker with environmentally friendly clay, cutting up to 20% of CO2 emissions compared to current practices on site. The order includes one of the world’s largest gas suspension calciner systems and a complete grinding station adding another 120 % grinding capacity.

In what will become one of the world’s largest clay calcination installations and the second record-breaking clay calcination order, FLSmidth is set to provide significant reductions in carbon emissions to CBI Ghana Ltd.’s cement production outside of Accra in southern Ghana. Together with the new grinding station, the Swiss owned company expects both financial and environmental return-on-investment from lower specific CO2 emissions, energy- and fuel savings, and reduced costs from clinker imports.

“Ghana is the perfect location for using clay as an environmentally friendly alternative to clinker,” says Frédéric Albrecht, CEO at CBI Ghana Ltd. “West Africa is traditionally a clinker- and cement importing region due to the lack of suitable limestone reserves. Developing countries with their young populations and a growing need for infrastructure and housing represents the future in cement consumption. Calcined clay cements are the most sustainable alternative to traditional clinker-based cement. With the support from FLSmidth, we will be able to operate clay calcination on a large scale,” Frédéric Albrecht concludes.

Using calcined clay to minimise the need for traditional, carbon-intensive clinker is a key technology in eliminating the environmental footprint from cement production, which today accounts for 7-8% of the world’s CO2 emissions.

“In the light of the commitments made by the international community – most recently at COP 26, the CBI Ghana project is yet another example of how the cement industry is responding to the need for more environmentally friendly processes. We are very excited to work with CBI Ghana on the project that sets a new standard for green cement,” says Carsten Riisberg Lund, Cement Industry President, FLSmidth.

“Using clay as a supplement in the cement production is not new – it has been done for decades. But, with our new clay calciner system, we can produce a highly reactive clay that is able to substitute between 30-40% of the clinker in the final product, resulting in up to 40% CO2 reductions per ton of green cement compared to traditional OPC cement,” Carsten Riisberg Lund adds.

The ability to significantly reduce both emissions and fuel consumption, makes the FLSmidth clay calciner system a flagship offering in FLSmidth’s MissionZero programme, which is the sustainability ambition to enable cement producers to operate plants at zero emissions by 2030.

The contract became effective and booked as order intake in Q1 2022.