Facilitating storage, flow and conveying

Standard Industrie International designs and manufactures equipment that facilitates the storage, flow and conveying of powders and bulk materials. Constant innovation is the motto of the company, which offers equipment at the forefront of technology and increasingly efficient. Founded in 1978 by Hervé Simoens, the company now operates worldwide through an extensive network of subsidiaries and agents. It has developed its activity and offers its costumers a wide range of products divided into four categories:

The air cannons “Airchoc” (Fig. 1)

The vacuum units (Fig. 2)

The optimization system for conveyor belts “Liftube”

Cleaning of silos and hoppers “Gironet”

The Liftube takes off in Latin America

The creation of a subsidiary in Mexico (north of the capital) in 1998 has developed into a real asset to the company. A few figures: Since the opening of the subsidiary in Mexico, more than 800 m of Liftube were installed in South America while over 7500 m of Liftube (Fig. 3) are already installed worldwide. It is indeed crucial to Standard Industrie that customers in South America have a local contact with professionals who can advise them and follow their installation projects.

Applications in cement plants

With cement plants, the story of the sealing system Liftube, started with two projects for El Salvador and Peru, soon followed by another installation in Colombia (Fig. 4) for the Holcim Group. The problem faced by Holcim Apasco was the transport of alternative fuels for powering the kiln. The fuel consists of pieces of plastic, grease or oil stained fabrics, pieces of wheels or tyres. The disadvantage of these materials lies in the fact that they are very light and therefore volatile, hence the importance of finding a solution to avoid any loss of material. Cleaning work was required daily in noxious and persistent oil and diesel odours. The installation of 145 m with four Liftube belts has solved this issue since the material is now confined, without any risk of loss. On the other hand, the working conditions of the operators have been considerably improved as they are no longer in constant contact with unhealthy odours.

The company Cementos Lima in Peru, who profits from the many advantages of the Liftube, installed 15 m of Liftube on two conveyors. The goal of the Liftube system was to reduce dust emissions from the loading point to the unloading point. Therefore, instead of being in contact with fixed rollers, the belt is running on a horizontal tilting center roll. A removable cover is fitted all over to ensure the reduction of dust emission on the conveyor. In summary, by installing this system, Cementos Lima has now improved the guarantee of a high quality products. Contamination issues were completely eliminated during the transport of material. Another installation project was launched at Maya Maya Supercemento in El Salvador.

The Cemex Mexico Group also chose the Liftube for an installation of 185 m to improve the sealing property of conveyor belts (Fig. 5). The reduction of dust emission of almost 95 %, helped the cement plant to huge savings in maintenance costs. The Liftube is a tremendous asset with regard to compliance with rules and environmental norms. Cemex Mexico really got interested in the material recovery aspect of the Liftube, since large amounts of material are lost throughout the transport of material and during unloading. Being completely covered, the product does not spread everywhere and cleaning costs are saved. The conveyor belt and the rollers are easily accessible thanks to tilting supports. This patented system is available as standard modules, evolutive, very easy to install on new or existing conveyors.

Safe and efficient installation

Safety is a key factor when it comes to making a decision. Indeed, the Liftube does not contain any sharp angles in its lateral area, which is a sensitive area very prone to accident. With an easy installation, this modular system adapts to the desired length depending on the site constraints. A few figures: an installation of 27 m, of a speed of 1.5 m/s, for a flow of 180t/h. The Liftube continues to be attractive to the cement factories of South America with current projects in Mexico, Argentina and most recently in Chile with an installation at Cales Inacesa for several tens of meters Liftube.

New solutions

Today, Standard Industrie markets its latest innovation, the Liftube High Temperature, especially designed for the transport of hot clinker and high temperature bulk products, always with the same advantages in terms of sealing properties, safety and return on investment. Two new solutions for conveyor belts can be offered generally:

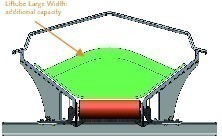

Liftube Large Width

The Liftube Large Width (Fig. 6) can carry a greater quantity of products. With a belt width ranging from 1000 mm to 1600 mm, the Liftube Large Width optimizes the sealing and the safety of any conveyor belt, reducing dust emissions, while complying with the norms.

Liftube High Temperature

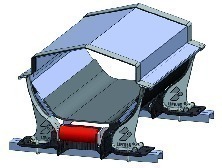

The Liftube High Temperature (Fig. 7) was specially designed for the transport of products over 120 °C. With a resistance to a maximum temperature of 300 °C, the Liftube High Temperature is the first concept for optimizing the sealing of conveyor belts for transport of product at high temperatures retaining the advantages of the Liftube standard.

Conclusions

The Liftube can carry powder products of very fine particle size (such as cement, lime, etc.) as well as products of large particle size (such as limestone, ore, etc.) and very abrasive materials (alumina, manganese, etc.). For products at risk, the Liftube ATEX meets the Area 21 norm. Accessories are available to enhance safety conveyors (pinch point protections, scrapers). In addition, the Liftube is guaranteed for three years by the company. Latin America is a preferred market for Standard Industrie which wishes to expand its activities and increase its reputation.

www.standard-industrie.com