Use of slide gates in the cement industry

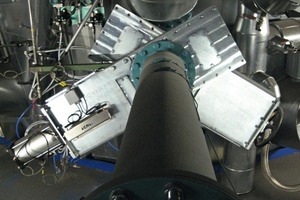

Slide gates are used in the cement industry to shut off silos, bins, containers and cyclones. A further field of application is their use as a shut-off device beneath proportioning machines, such as screw conveyors and airslides. The technical requirements are varied, from a simple emergency slide valve up to flow regulating valves. The requirements cover the pressure tightness during the flow and towards the outside with low leakages for many different bulk solid properties and temperature ranges. The sizes depend on the connecting flange of the units in front of or behind the slide gate as well as on the grain size of the bulk material flowing through. In explosion-prone areas slide gates are used as quick-closing valves (closing time in ms), as a decoupling system and as an ATEX device with the additional function “flameproof” according to ATEX RL 94/9/EG. ATEX slide gates with the additional function “flameproof in closed state” are used as maintenance slide gates in front of proportioning units to decouple a possible explosion in containers arranged above during maintenance work. In addition, this type of slide gate is also used as a shut-off device behind equipment and containers also to ensure an explosion decoupling in the closed state of the slide gate according to the danger analysis (Fig. 1).

Design of the new slide gate type FSZ

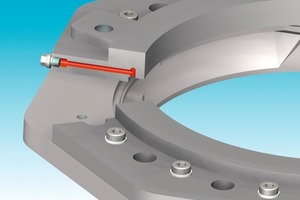

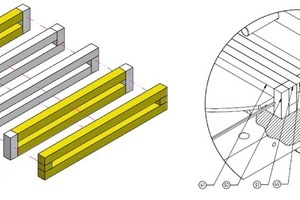

The design of the FSZ slide gate is based on the flexible multi slide gate FM (Fig. 2), which have proved their effectiveness for more than 60 years. Over 10 000 units have been installed in many different branches and for a variety of different applications. The casing of the new slide gate is of solid casting, type GG25, and will be additionally reinforced depending on the size, so that the pressure shock resistance of up to 10 baro is ensured for the nominal diameters of DN 200 to DN 800. The straight and free passage is optimal for the material flow. Optionally, the area can be blown clean via the scavenging air bore (Fig. 3) at the front side, thus avoiding a build-up of bulk solids in the closing area of the casing.

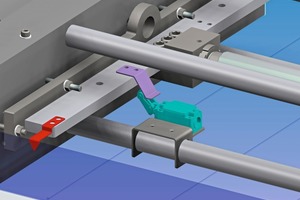

Compared to all other vario-slide gates, the Jaudt model shows a distinct difference as regards the sealing of the slide gate plate. The fivefold stuffing-box packing (Fig. 4) can be replaced as a built-in unit enabling the operator to maintain the unit without dismantling it. During commissioning the adjustment of the manufacturer should be checked after various operations and the packing should be re-tightened, if necessary. Sealing during passage is carried out by means of a laterally rotating 0-ring. The tightness during the passage corresponding to leakage rate B and towards the outside to leakage rate C according to EN12266-1:2003 are shown in Table 1.

The slide gate can be used in explosion-prone areas of dust 1D/2D (inside/outside) and gas 3G/2G IIB. Furthermore, the slide gate is pressure shock resistant up to 10 baro and additionally flameproof in the closed state from top to bottom up to 10 baro. In order to ensure the closed state and, consequently, the protection against ignition breakdown (Fig. 5) for a KSt value ≤ 200, Jaudt offers a safety limit switch in addition to the inductive limit switches ON/OFF to monitor this position. Only then does the slide gate meet the flameproof requirements in the closed state because the inductive limit switch “OFF” is not appropriate for this due to its position inaccuracy.

The sizes DN 200 to DN 800 are determined by the nominal diameter of the unit, on which the slide gate is installed upstream or downstream by the operator or plant constructor. The type of the slide gate is determined by the data submitted by the customer: bulk solids, bulk solids particle size, flow properties, operating temperature, pressure difference, place of installation (e.g. explosion-prone area) and conditions of operation, e.g. determined by means of the danger analysis. A vario-slide gate is recommend to meet the following requirements:

free passage of bulk solids

tightness during passage and towards the outside > 0.5 baro

installation in explosion-prone areas

flameproof during passage from both sides and towards the outside

measures to avoid build-up in the passage

easy maintenance

All other types of slide gates will not meet the requirements one hundred per cent and will not ensure the operational safety, even if initally they are more cost-effective and will compensate for the drawback due to the cost advantage.

TEXT Robert Roßkopf, Managing Director, JAUDT Dosiertechnik Maschinenfabrik GmbH, Augsburg/Germany