Heatcatcher Ltd completes “waste heat to power” system for Steetley Dolomite

“Waste heat to power” specialists Heatcatcher Ltd have announced that their first Heatcatcher System, at the Thrislington lime plant near Durham, is now fully operational. The system, which cost 1566 million Euros (£ 1.3 million) to design, build and deliver, is on course to deliver a return on the investment within five years. Early data indicates that it can be expected to generate net power of around 3000 MWh annually, equivalent to 7500 hours of carbon-free electricity. In total, CO2 emission will be reduced by 1600 tonnes per year.

Steetley Dolomite are keen to make further investments across its two plants after securing a 4,8 million Euro (£ 4 m) funding package from HSBC’s Nottinghamshire commercial team.

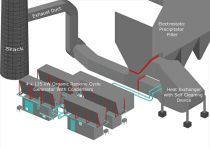

The Heatcatcher System works by using the waste heat to vaporise a refrigerant, which in turn drives a rotary generator. The variable frequency and voltage output of the generator are converted to match the grid, and this electrical output is fed back into the plant’s power supply. Every stage of the process has been calibrated to minimise energy losses within the system. In total, each plant fitted with the system recovers 4 MWh of thermal power, and converts it to 0.5 MW of cheap, low-carbon electrical power.

//www.heatcatcher.com" target="_blank" >www.heatcatcher.com:www.heatcatcher.com