High-precision work for main gear replacement on a tube mill

Recent repair and maintenance work on the around 50-year-old Krupp two-chamber tube mill at the Burglengenfeld cement plant confronted Keller GmbH with a number of challenges. A detailed schedule and the company’s many years of design experience nonetheless made it possible to complete these repairs in three weeks.

1 Introduction

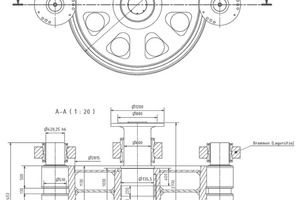

The Krupp two-chamber tube mill at the Burglengenfeld cement plant has been in service for about fifty years. It has a diameter of 3.8 m and a length of 14.1 m, thus occupying a considerable portion of the mill building. The layout of this structure has significantly changed since the 1960s, presenting Keller GmbH, entrusted with the repair and maintenance work on the cement mill, with a number of challenges: the constricted space necessitated positioning with millimetre accuracy of the necessary mobile installation cranes. The floor of the shop would not have stood up to the...