Improving the thermal insulation

properties of thin-bed mortar

Part I: Impact evaluations of various

admixtures on material engineering

parameters

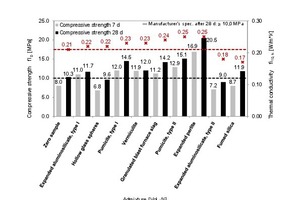

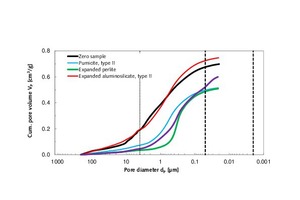

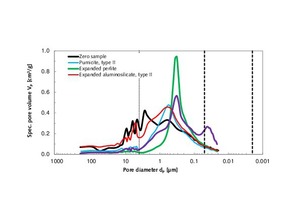

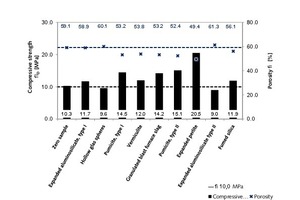

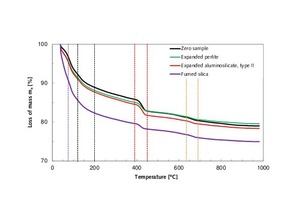

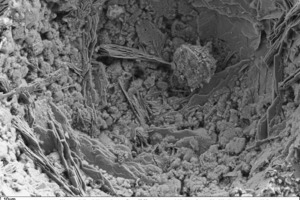

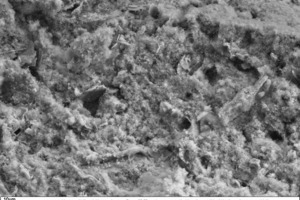

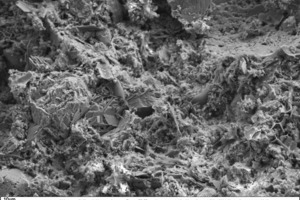

Monolithic walls erected with an appropriately modified thin-bed mortar should show superior thermal insulation properties. Admixing 10 vol.% fumed silica proved to reduce by 19% the thermal conductivity of a typical thin-bed mortar belonging to compressive strength class M 10. Simultaneously, it also improved the mortar’s compressive strength by nearly 16 %. The investigations also showed that an admixture of expanded perlite can increase the compressive strength by 99 %.

1 Introduction

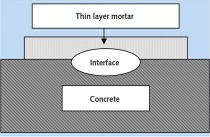

Thin-bed cement mortar is often used for masoning up such precision-ground, monolithic wall-building materials as bricks, autoclaved aerated concrete units (Ytong), or building blocks of pumicite, expanded clay or sandy limestone [1–3]. The corresponding material engineering parameters are governed by the applicable DIN specifications [4–7], which prescribe, for example, a compressive strength level of βD ≥ 10.0 MPa for class-M 10 mortar after 28 days of curing [8].

According to one market analysis, the thermal conductivity of products in this mortar category has been stagnating...