Intelligent structuring and segmentation of piping

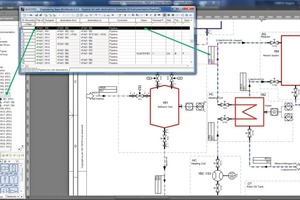

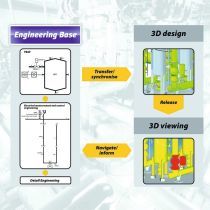

Aucotec AG from Hannover, Germany has developed a new function for its process engineering-oriented software system Engineering Base (EB) instrumentation, which now makes the piping that is defined in P&ID a lot “smarter”. The new version EB 6.5.0 allows information on the flow direction, media, temperatures and pressures to be added to the P&ID. The automated target tracking shows both the beginning and the end of the piping as well as the topology of all sub-segments with all connected components such as valves, pumps, flaps or flanges.

The flow direction gives rise to the sequence of devices, which is important for pipe manufacturers and the 3-D connection. The topology information forms the basis of the subsequent isometric drawing, which can never be fully derived from a P&ID.

Each sub-segment of a piping knows to which main pipe it belongs, the devices which mark the beginning and end, and the other sub-segments that are also involved. In addition, EB automatically displays the standard representation of the connection types for the piping, which is usually determined by the medium.

With this development stage of the CAE platform EB, Aucotec has laid the foundation for supporting pipe class-based workflows. This enables significantly improved material selection in future based on the standardized and tested pipe classes that are defined in the system. Engineering Base thus supports all national and international standards as well as individual internal standards.

//www.aucotec.de" target="_blank" >www.aucotec.de:www.aucotec.de