Investigations into the mechanical

properties of Portland slag cement based on GBFS and steel slag

The aim of the study is to investigate the utilization of steel slag in the manufacture of Portland slag cement (PSC) by partial replacement of granulated blast furnace slag (GBFS) with steel slag. In spite of its nonconformity in terms of glass content (≥85 %), as specified in Indian standard IS:12089-1987 for slag to be used in the manufacture of PSC, different PSC blends were prepared using 40, 45, 50 and 55 wt.% of steel slag to investigate the sole use of steel slag in cement. PSC blends were also prepared by partial replacement of 15 % the granulated BF slag by steel slag so that the effective glass content of the composite slag fulfilled the criterion of the Indian standard. These slag cement blends were evaluated for their physical characteristics, such as consistency, setting time, compressive strength, etc. The effect of curing in different aggressive media on the compressive strength of slag cements containing optimum levels of GBFS and steel slag was studied by immersing the hardened cement mortar cubes in solutions, i.e. sulfate (0.33 N, Na2SO4) and chloride (0.5 N NaCl) salts, along with plain water for up to 6 months. This indicated that the resultant PSC blends were resistant to aggressive environments. The study showed that steel slag in combination with granulated BF slag could be used in the manufacture of Portland slag cement.

1 Introduction

Formulations of blended cements based on natural or synthetic inorganic minerals are associated with the conservation of resources, energy and cement along with lowering the clinker factor in cement. The mineral balance in nature is disturbed by the depletion of natural minerals on one hand and the rapid growth of by-products from increased industrial activity on the other. Energy has to be expended to form the hydraulic clinker minerals in Portland cement but industrial waste materials containing useful minerals with intrinsic hydraulic potential offer a ready-made solution.

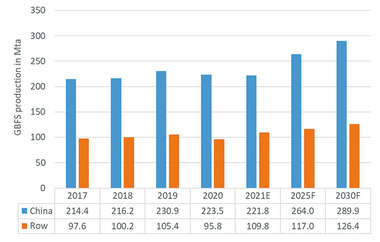

Steel slag, a by-product of steel making, is produced during the separation of the molten steel from impurities in a steel-making furnace by the Linz-Donawitz (LD) process. More than 400 kg of slag are generated per ton of steel produced in an integrated steel plant, mainly during the production of iron in blast furnaces and of steel in oxygen blowing converters. At presently, all blast furnace slags are wet-granulated and utilized as latent hydraulic agents in the cement industry. However, such a proven technical solution does not exist for steel slag, which accounts for about one third of the total slag produced in a plant and remains unutilized. Earlier studies revealed that steel slag can be used in the cement and construction industries as a raw mix component in clinker production because the lime in de-carbonated form in the steel slag reduces the heat of calcination and the iron-bearing minerals facilitate the clinker-forming reaction [1, 2]. It can also be used for partial replacement of Portland cement [3-6] in composite Portland cement based on steel slag-fly ash [7], as asphalt concrete aggregate for road construction and as armour stone for hydraulic structures [8], as a flux material instead of lime and limestone in various metallurgical process and in steel-making after dephosphorisation [9, 10] and in the development of fly ash-LD slag bricks [11] etc. Wimmer et al., 2015 [12] reported the use of the LD slag as a cement clinker substitute by modifying the slag with considerable amounts of alite (C3S) formed during solidification, thus increasing its hydraulic properties. The presence of free lime in steel slag restricts its use in civil engineering due to the dimensional instability [13, 14]. The effect of free lime in steel slag was countered by low temperature incineration and alkaline solution immersion [15, 16]. Steel slag cement, composed mainly of steel slag, GBFS and Portland cement, has been commercially available in China [5]. This type of cement has the advantages of lower energy cost, higher abrasion resistance, lower hydration heat evolution and higher later age strength development but the disadvantage of lower setting time and lower early strength when compared with Portland cement.

About 2.0 million t of steel slag are currently generated annually at M/s Tata Steel Limited, Jamshedpur/India, of which about 1.0 million t remains unutilized. In view of the quantity of steel slag that has accumulated, this paper describes the study of the use of steel slag in combination with GBFS in the manufacture of Portland Slag Cement because the nonconformity of steel slag with the Indian standard IS: 12089-1987 with respect to glass content has restricted its sole use for making slag cement.

2 Materials and experiments

Steel slag (LD-1, LD-2), granulated blast furnace slag (BF-1, BF-2), OPC clinker (CL-1, CL-2) and gypsum samples were collected and analysed for constituent oxides as per Indian standard IS: 4032-1985 and for mineralogy by X-ray diffraction (XRD) (Rigaku International, Japan, D-MAX 2200V/PC) using nickel-filtered CuKa radiation (λ=1.5405Å), scanning from 5 to 65o 2θ, with increments of 0.02o and counting time of 1.2 seconds per step, accelerated voltage of 40 KV and current of 30 mA. The morphology and granulometry of the clinker was investigated on polished sections using a NIKON POL 600 reflected light microscope equipped with image analyzer. The steel slag as well as GBFS samples were analysed for heavy elements using Inductive Coupled Plasma Spectrometer (ICP-OES) (Model: VISTA-MPX, Varian Make). The slag activity indices of the GBFS and steel slag were determined according to ASTM C 989-99. The Bond grindability index of slag was estimated as per Indian standard IS: 10218-1982.

Different cement blends were prepared by utilizing 40, 45, 50 and 55 wt. % steel slag, while maintaining a Blaine fineness of 360±10 m2/kg, in order to investigate the feasibility of using steel slag alone in the manufacture of slag cement in spite of its nonconformity to IS: 12089-1987 for glass content (≥85%). Control samples were also prepared using equivalent levels of GBFS for comparative evaluation of steel slag and GBFS. Different composite slag samples were also prepared by blending 90 wt.% granulated BF slag (BF-1/BF-2) and 10 wt.% steel slag (LD-1/LD-2), so that the composite slag fulfilled the requirement of glass content, ≥ 85 % as specified in IS: 12089-1987 for slag in a further attempt to make Portland slag cement while utilizing steel slag with GBFS. Another set of composite slag samples was also prepared by blending 85 wt.% GBF slag (BF-1/BF-2) and 15 wt.% steel slag (LD-1/LD-2), where the composite slag just met the criterion of glass content as specified above, in order to accommodate a higher percentage of steel slag in cement making. Different slag cement blends were prepared using 40, 45, 50 and 55 wt.% levels of the composite slag samples mentioned above while maintaining a Blaine fineness of 360 ± 10 m2/kg. The mechanical properties of the resultant cement blends compared with the control blends prepared using similar levels of GBFS were studied using the different test procedures described in Indian standard IS: 4031 (Part-2,3,4,5,6 and 9). Selected slag cement blends were hydrated for different time intervals of 3, 7, 28, 90 and 180 days while maintaining a water/cement ratio of 0.4. The hydration products were studied by X-ray diffraction (XRD) and for morphology of the hydrated cement pastes by Scanning Electron Microscope (SEM).

The effect of curing under different aggressive media on the compressive strength of Portland slag cement blends was studied by immersing the hardened cement mortar cubes of cement blends in different solutions, i.e. sulfate (0.33 N, Na2SO4, pH-5.99) and chloride (0.5N NaCl, pH-6.43) salts, along with plain water (pH 7.0) up to a period of 6 months and then crushing them to determine the compressive strength.

3 Results and discussion

3.1 Characterization of steel slag

and other materials

Chemical analysis of steel slag, LD-1 and LD-2 indicated the presence of 49.17 and 49.91 % CaO, 13.56 and 13.16 % SiO2, 21.87 and 22.82 % Fe2O3,4.78 and 4.50 % MgO (Table 1) along with 3.45 and 7.72 % free CaO, respectively. Two different steel slag samples were taken to investigate the extent of volumetric expansion of cement blends due to different free CaO contents in steel slags. The heavy elements in the steel slags were determined (Table 2). The chemical compositions of the steel slags and GBFS samples showed their conformity to the chemical requirements of IS: 12089-1987 (Table 3). The glass content, as determined by optical microscopy on steel slags LD-1 and LD-2, was found to be 39 and 40 % respectively as compared with the minimum value of 85 % for slag as specified in the Indian standard. However, the glass content in GBFS samples BF-1 and BF-2 was determined as 92 and 93 % respectively, thus fulfilling the above requirement for glass content.

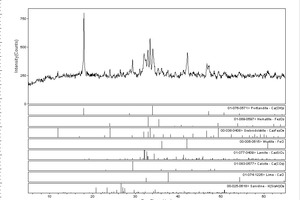

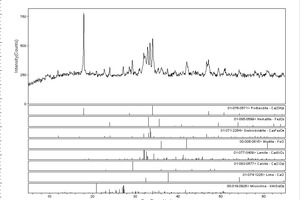

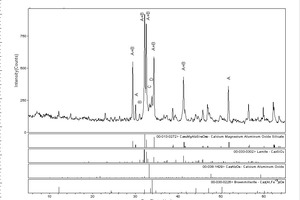

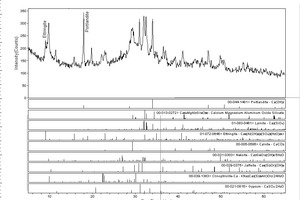

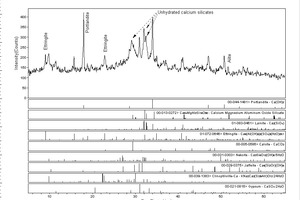

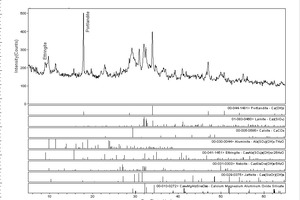

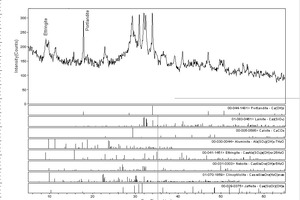

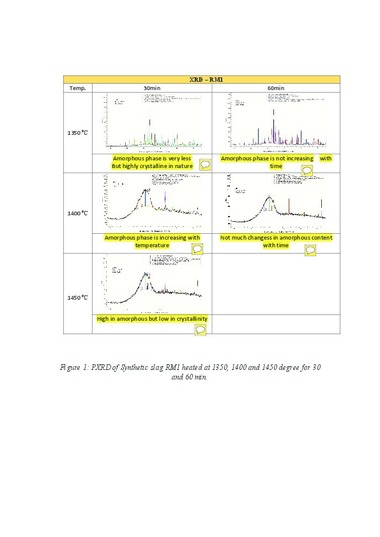

X-ray diffraction analysis showed that the diffraction pattern of steel slag was very complex with several overlapping peaks, with portlandite [Ca(OH)2] as the most abundant mineral phase and hematite [Fe2O3], larnite [Ca2SiO4], wusite [FeO], calcite [CaCO3], lime [CaO] and sanidine [K(Si3Al)O8] as major and minor mineral constituents (Figures 1a and 1b). Diffraction peaks corresponding to free CaO in steel slag LD-2 was found to be more prominent than in steel slag LD-1. The presence of free lime is an indication of the potential for volumetric instability and expansive hydration reaction [17] whereas calcium silicate is an indication of the cementitious properties of the steel slag.

The slag activity index of steel slags LD-1 and LD-2 was found to be 34.38 and 43.76 % respectively at 28 days as compared to 65.63 and 65.70 % for the granulated BF slags BF-1 and BF-2. The Bond grindability indices of steel slags showed their harder nature (22.4 and 21.6 kWh/short-ton) as compared to granulated BF slag (16.8 and 15.7 kWh/short-ton).

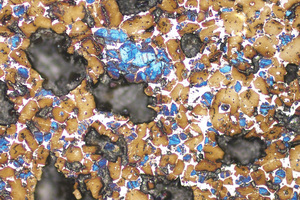

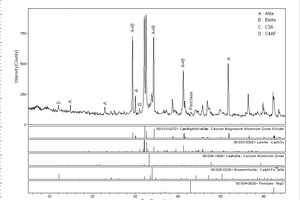

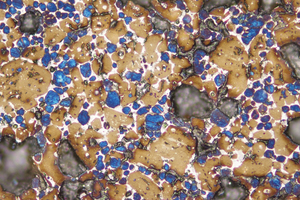

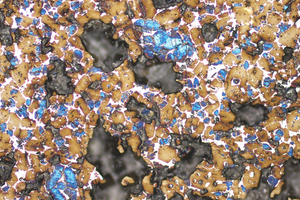

The chemical analysis of Portland clinkers CL-1 and CL-2 showed the presence of the usual oxide constituents, with 0.57 and 0.48 % free lime indicating their well burnt nature (Figures 2a and 2b). Semi-quantitative estimation of clinkers by XRD (Rietveld refinement method) showed 56 and 46 % alite, 20 and 27 % belite, 6 and 7 % C3A and 13 and 14 % C4AF. Two clinker samples CL-1 and CL-2 with different alite contents of 56 and 46 % were taken to study the extent of strength development of cement blends on addition of different levels of granulated BF slag and steel slag mixed in different proportions. The microstructure of clinkers CL-1 and CL-2 showed moderately developed and inhomogeneously distributed clinker phases. The majority of the alite grains were observed to be pseudo-hexagonal to hexagonal in shape whereas most of the belite grains were rounded to sub-rounded in shape, as shown in Figures 3a and 3b. The average grain size of the alite and belite was found to be 31 and 27 and 34 and 28 μm respectively. The Bond grindability indices of the above clinker samples were found to be 13.9 and 19.1 kWh/short-ton, indicting the harder nature of clinker CL-2 as compared to CL-1. Chemical analysis of the gypsum sample showed its high purity with gypsum [Ca(SO4)(H2O)2] as the major mineral constituent.

3.2 Preparation and evaluation of PSC blends prepared using steel slag

Different cement blends were prepared using 40, 45, 50 and 55 wt.% of steel slag (LD-2), while maintaining a Blaine fineness of 360±10 m2/kg (Table 4), in order to study the feasibility of using steel slag alone for producing PSC in spite of its nonconformity to Indian standard IS: 12087-1997 for glass content (≥ 85 %). Control samples were also prepared using equivalent levels of GBFS (BF-2) for comparative evaluation of steel slag with GBFS.

Slag cement blends PSC-LD-40, PSC-LD-45, PSC-LD-50 and PSC-LD-55 were analyzed for their oxide constituents and for LOI, MgO, SO3, Na2O, K2O, Cl, sulfide sulfur and insoluble residue. This showed their conformity to the chemical requirements of Indian standard IS: 455-2015 [18] specified for Portland slag cement (Table 5).

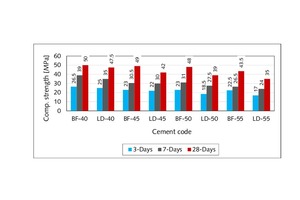

Slag cement blends were characterized for different physical characteristics such as Blaine fineness, consistency, setting time, compressive strength and soundness. The Blaine fineness of cement blends (PSC-LD-40 to PSC-LD-55), determined by the air permeability (Blaine appa-ratus) method as per IS: 4031(2)-1999, was found to be 360±10 m2/kg, which is comparable to the control samples PSC-BF-40 to PSC-BF-55. The water requirement to produce cement paste of normal consistency was slightly reduced, from 27-28% to 25-26%, by the addition of steel slag when compared with the control cements when measured according to IS: 4031(4)-1998. The initial and final setting times, determined as per IS: 4031(5)-1998, of the cement blends were in a comparable range (IST: 120-140 minutes, FST: 180-200 minutes) indicating the insignificant effect of adding of steel slag on the setting behaviour of cements. The compressive strengths, measured as per IS: 4031(6)-1989 on 1:3 cement-sand mortar of cement blends PSC-LD-40 and PSC-LD-45 were found to be lowered by 5 to 10% at all ages as compared to their respective control cements whereas a 15-20% reduction in strength was noticed with cement blends PSC-LD-50 and PSC-LD-55 containing higher levels of steel slag, indicating the poor hydraulic nature of steel slag. The trend of the compressive strengths of the control cements (PSC-BF-40 to 55) and the resultant cement blends (PSC-LD-40 to 55) showed a reduction in strength on adding increasing levels of steel slag (Figure 4). The PSC blends were investigated for dimensional stability (IS: 4031(3)-1988) and showed that the values of linear expansion and the autoclave test were within range of the Indian standard in spite of the high free lime content in steel slag LD-2. This means that all the cement blends prepared using steel slag alone fulfilled the chemical and physical requirements of Indian standard IS: 455-2015 specified for slag cements.

3.3 Preparation and evaluation of PSC blends

prepared using a mixture of BF and steel slag

Due to the nonconformity of steel slags LD-1 and LD-2 to Indian standard IS: 12089-1987 for glass content, as discussed in sub-section 3.2, steel slags could not be used alone in the manufacture of Portland slag cement. In order to investigate the use of steel slag in cement that meets the Indian standard criterion, different composite slag samples (SL-1/SL-3) were therefore prepared by blending 90 wt.% granulated BF slag (BF-1/BF-2) and 10 wt.% steel slag (LD-1/LD-2) (Table 6) so that the composite slag fulfilled the requirement for glass content (≥85 %) as specified in the Indian standard. In order to accommodate a higher percentage of steel slag in the cement another set of composite slags (SL-2/SL-4) was also prepared by blending of 85 wt.% BF slag (BF-1/BF-2) and 15 wt.% steel slag (LD-1/LD-2), so that the composite slag just met the criterion for glass content.

Different cement blends (Sets: 1-4) were prepared using 40, 45, 50 and 55 wt.% of composite slag (SL-1 to SL-4), while maintaining a Blaine fineness of 360 ± 10 m2/kg (Tables 7 and 8), to investigate the role of steel slag in the manufacture of slag cement. Control cement blends were also prepared using the same levels of granulated BF slag (BF-1 and BF-2) for comparative studies.

Chemical analysis for LOI, MgO, SO3, Na2O, K2O, Cl, sulfide sulfur and IR of the above cement blends prepared in Sets-1 to 4 showed their conformity to the chemical requirements of the Indian standard IS: 455-2015 laid down for slag cement.

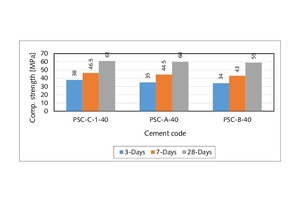

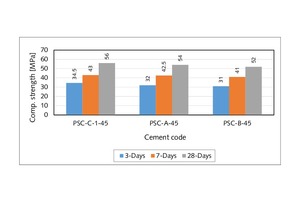

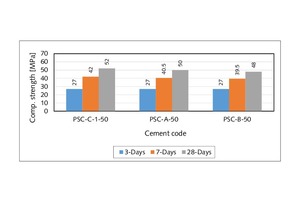

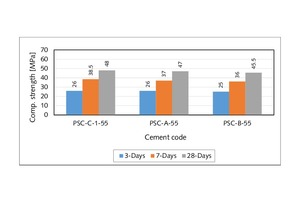

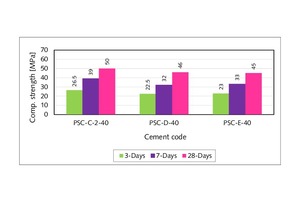

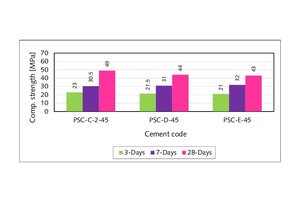

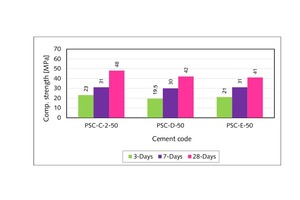

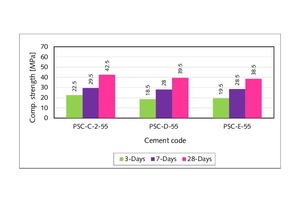

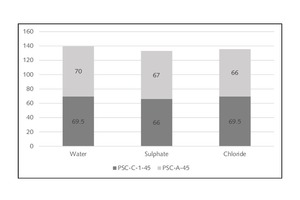

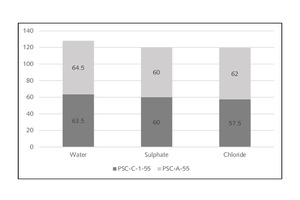

The physical characteristics of the slag cement blends when compared with the control cements were investigated in accordance with the different Indian standard test procedures, as discussed earlier. The water requirement to prepare cement paste of normal consistency was found to be in the range of 27.2-27.8 % for Set-1 and 25.6- 26.0 % for Set-2, as compared to their control counterparts, where the values were 26.6-27.2 %. In the case of Sets 3 and 4, the values of normal consistency were 27.2-27.4 and 25.8-26.6 % respectively as compared to the control cements (27 to 28 %). The initial and final setting times of the resultant cement blends were slightly lengthened in the presence of steel slag in spite of comparable SO3 contents. The compressive strengths of the cement blends prepared in Sets 1 and 2 were found to be lowered by 6-10 % (Figures 5a and 5b) at all ages, but particularly at early ages at the replacement level of 40 and 45 %, whereas a 10-15 % reduction was noticed in case of Sets 3 and 4 (Figures 6a and 6). The marginal reduction in strength development in case of Sets 3 and 4 could be attributed to the inferior quality of clinker CL-2 with 46 % alite content (OPC-2; compressive strengths at 3, 7 and 28 days were 37.0, 48.5 and 57.5 MPa) used in the preparation of cement blends when compared with Sets 1 and 2, where clinker CL-1 with a 56 % alite content (OPC-1; compressive strengths at 3, 7 and 28 days were 40, 54.5 and 64.0 MPa). However, at the 50 and 55 % replacement level, the compressive strengths were found to be lowered by 4-5 % in the case of Sets 1 and 2 and by 10-12 % for Sets 3 and 4. The comparatively lower percentage reduction in compressive strength with addition of 50 and 55 % composite slags, as compared to 40 and 45 %, showed that steel slag imparts cementitious properties owing to the presence of calcium silicates. It could therefore be inferred from the above investigations that Portland slag cements, PSC-B-50 and PSC-E-50 prepared using 50 % composite slags SL-1 and SL-3 (mix of 85 % GBFS and 15 % steel slag) respectively achieved the level of compressive strength attained by the control Portland slag cement blends prepared using 55 % granulated BF slag as shown in Figures 5c, 5d, 6c and 6d respectively. These blends were also tested for soundness and showed a higher degree of stability in terms of linear and volumetric expansion. The evaluation of slag cement blends prepared using a mixture of granulated BF slag and steel slags therefore fulfilled all the chemical and physical requirements of the Indian standard IS:455-2015 specified for Portland Slag Cement.

Earlier investigations showed that substitution of 15% OPC clinker by electric arc furnace steel slag did not reduce strength significantly, i.e. 64.4 MPa compared to 66.5 MPa for the control cement, and that further treatment of steel slag led to high strength and a potential for further increase after 28 days [19]. Steel slag cement cured in alkaline solution gave higher strengths due to the accelerated hydration reaction [3,14]. Kourounis et al. [20] reported the use of steel slag in the production of composite cements of the strength classes 42.5 and 32.5 in EN-197-1. In the composite system comprising steel slag, BF slag and Portland cement in the ratio of 25:25:50, the mortar strength of cement increases with increasing fineness of the steel slag powder but is reduced at 3 days, which could be offset by using an alkali activator [4]. The addition of steel slag and granulated blast furnace slag to Portland cement showed an acceptable final strength though a longer hardening period [21]. Xiaowei et al. [4] studied the gradual increase in expansion rate with increasing levels of steel slag in composite cement owing to the higher free lime content in steel slag.

3.4 Hydration studies of PSC blends

using XRD and SEM

A slag cement (PSC-A-55) and a control cement (PSC-C-1-55) were hydrated by maintaining a water/cement ratio (w/c) of 0.4 and were kept in sealed plastic vials for different hydration periods up to 180 days at the ambient temperature of 27±2oC. After stipulated periods of hydration the hydrated cement pastes were washed with acetone (99.5 % purity) to arrest hydration and dried in a laboratory oven at a temperature of 40±2oC. The hydrated cement pastes were studied for the development of hydration products by X-ray diffractometer using CuKα (1.542Å) and for morphology by scanning electron microscope (JEOL 6510 LV). Powder samples passing through a 45 µm IS sieve were taken for XRD studies. Ground samples of sizes 1-5 mm were prepared for SEM studies. Secondary electron images were recorded at an accelerating voltage of 15 Kv.

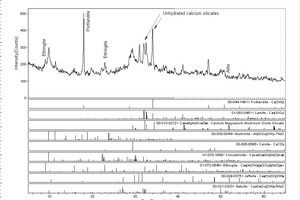

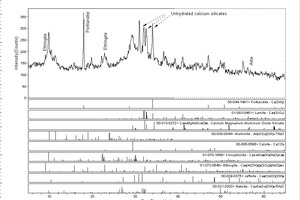

X-ray diffraction patterns of 3-day hydrated slag cement paste (PSC-A-55) showed the development of hydrated phases; portlandite [Ca(OH)2], ettringite [Ca6(Al(OH)6)2 (SO4)3(H2O)25.7] and calcium silicate hydrate phases (C-S-H); nekoite [Ca3Si6O12(OH)6.5H2O], jaffeite [Ca5(Si2O7)(OH)6], clinoptilolite-Ca [KNa2Ca2(Si29Al7)O72.24 H2O] and unhydrated calcium silicates, alite [Ca54MgAl2Si16O90] and belite [Ca2SiO4] (Figure 7b). Similar phases were identified in the hydrated control cement paste (PSC-C-1-55) (Figure 7a). Regourd [22] and Uchikawa [23] reported similar principal hydrated phases in slag cement and Portland cement with a comparatively lower quantity of Ca(OH)2. Monitoring the diffraction line d=1.81Å in the diffraction patterns showed that more alite had participated in the hydrated reaction in the control cement (Figure 7a) than in the resultant cement (Figure 7b), indicating a marginally higher degree of hydration in the presence of GBF slag. This correlates with the observed reduction in strength in the presence of steel slag. The addition of slag slows down the hydration of the blended cements due to the morphology of the C2S and the low content of calcium silicates [20]. A gradual increase in the intensity of portlandite [Ca(OH)2] was detected as the hydration reaction proceeded owing to growth of Ca(OH)2 crystals, indicating a higher degree of hydration. Similarly, the reduction in the intensities of the diffraction lines corresponding to calcium silicates (alite and belite) indicated their participation in the hydration reaction with time, as shown in the control cement blend (Figures 7b, 7d, 7f) in comparison to the resultant cement blend (Figures 7a, 7c, 7e). The gradual increase in the Ca(OH)2 diffraction peaks with a gradual reduction in the diffraction peaks of alite (C3S) and belite (C2S) showed an increase in the degree of hydration reaction with time. Hydration studies of cement paste (PSC-A-55) at all ages showed a hydration development that is more or less similar to the control cement (PSC-C-1-55) with a marginal difference in their integrated intensities that indicate the degree of hydration.

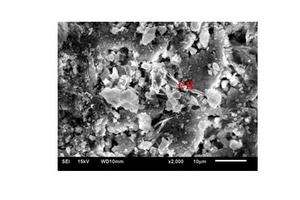

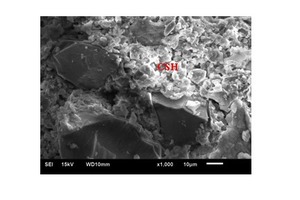

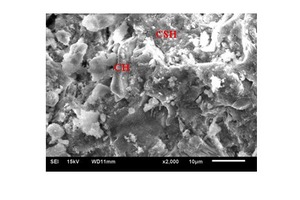

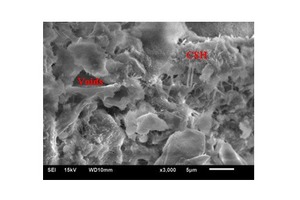

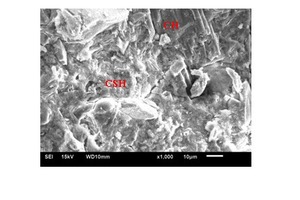

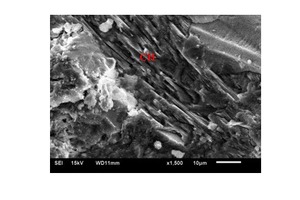

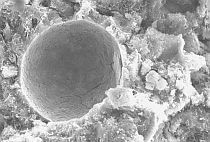

The morphology of 3-day hydrated control cement paste showed the development of porous calcium silicate hydrates (C-S-H) gel around the cement grains with the formation of ettringite and portlandite (CH) (Figure 8a). The hydrated cement matrix was observed to be denser as the hydration proceeds (Figure 9a). Abundant larger crystals of portlandite up to 35 µm were detected in the 28-day hydrated cement paste (Figure 10a). The morphology of the hydrated cement paste (PSC-A-55) showed the presence of relatively coarser slag particles when compared with the hydrated control paste due to the presence of coarse slag particles of sizes up to 100 μm with high interstitial porosity. The formation of small crystals (3 μm) of ettringite was observed in the interstitial pores along with formation of portlandite and C-S-H gel around the cement grains (Figure 8b). Most of the slag particles were unreacted and the interface between slag particles and C-S-H gel was not filled with any hydrated products. The density of the interstitial pores was significantly reduced as the hydration proceeded. Ettringite crystals up to a size of 6 μm were detected in the pores, air voids and interfacial zones (Figure 9b). A denser microstructure was observed in cement paste hydrated for 28 days. Ettringite crystals were detected in the pores and voids and portlandite crystals were present in abundance (Figure 10c). The morphology of the cement pastes showed a denser hydrated cement matrix in the hydrated control cement paste at all ages when compared with the hydrated steel slag cement paste. This was due to the formation of more porous interfacial zones between the unreacted slag particles and the C-S-H gel, resulting in a marginal reduction in strength.

3.5 Study of the resistance to aggressive

environments

Investigations into the effect of curing under aggressive environmental conditions (such as sulfate and chloride solutions) of slag cement blends PSC-A-45 (Figure 11a) and PSC-A-55 (Figure 11b) and their control counterparts PSC-C-1-45 and PSC-C-1-55 were carried out by determining the compressive strength of cement mortar cubes (cement: sand=1:3) immersed in sulfate and chloride solutions for 6 months. The compressive strength of mortar cubes immersed in plain water was also measured for reference. The results of the strength development of cement mortar cubes cured in sulfate and chloride solutions were found to be comparable to those of mortar cubes cured in plain water, showing that slag cements prepared using a combination of granulated BF slag and steel slag were resistant to sulfate and chloride solutions as shown in Figures 11a and 11b. Dhir et al. [24] and Maes [25] investigated the effects of chlorides and sulfates on the durability characteristics of concrete.

Duda [21] reported a distinct improvement in the sulfate resistance of Portland cement mixed with steel slag and granulated blast furnace slag. Jankovi´c et al. [26] studied the influence of aggressive solutions (sulfate and nitrate) on mortar and concrete and concluded that mortar and concrete made with a combination of cement and admixtures were not resistant to ammonium nitrate solutions but were resistance to sulfate corrosion. Fiertak and Stryszewska [27] investigated the chemical resistance of three-component binders, i.e. Portland cement, pulverised blast furnace slag and silica fume, immersed in ammonium sulfate solution by compression testing after 28 and 90 days.

4 Conclusion

1. The glass content in steel slag samples was 39-40 % and therefore did not meet the requirement of Indian standard IS: 12089-1987 for glass content (≥85 %) whereas the glass content in granulated blast furnace slag was 92-93 % and therefore fulfilled the above criterion.

2. The compressive strengths of PSC blends prepared by replacing Portland clinker by 40, 45, 50 and 55 wt.% steel slag alone showed a 15-20 % reduction in strength at all ages with increasing content of slag when compared to their control counterparts, indicating the hydraulic nature of steel slag owing to the presence of glass and calcium silicates.

3. Slag cements prepared using 50 % composite slag (85 wt.% granulated BF slag and 15 wt.% steel slag) in conformity to the criterion of glass content for slag, achieved the level of compressive strength attained by the control slag cement prepared with 55 wt.% blast furnace slag and fulfilled all the chemical and physical requirements of IS:455-2015 specified for PSC.

4. The use of up to 7.5 wt.% steel slag in combination with up to 42.5 wt.% granulated blast furnace slag was therefore found to be feasible for the production of slag cements, which were also found to be resistant to aggressive environmental conditions.

Acknowledgements

The work reported in this paper forms a part of study sponsored by M/s Tata Steel Limited, Jamshedpur/India. The authors are grateful to the Director General, NCB, for allowing publication of the paper.