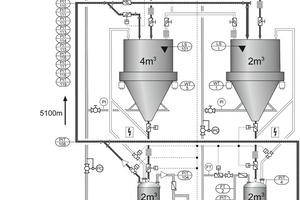

Long-distance conveyance using a pneumatic system

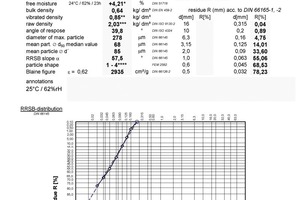

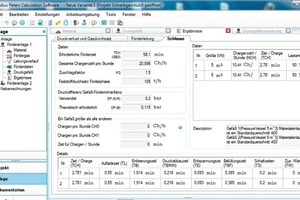

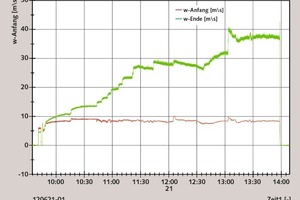

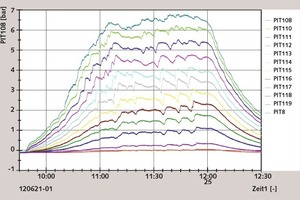

The basis for designing a pneumatic conveying system is precise knowledge of the material to be conveyed. This is gained by means of raw material analyses that determine, for instance, the granulometric distribution, bulk density, moisture content and surface properties. On the basis of the specified system parameters and the determined material data, the process technological designing of the system is carried out, generally using special computing programs.