Lords of the chains

For more than 100 years, chains have been made in the German town of Wickede. Today, Managing Director Alexander Koch is the third generation of his family to head Heko Ketten GmbH. The company started off in 1917, making chains for mining and agriculture, but its biggest customer today is the cement industry.

Partnership with customers

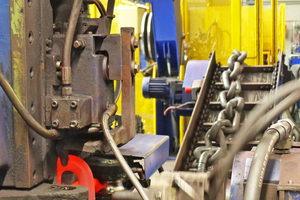

Together with two sister companies, the Heko Group manufactures steel round link chains, forged link chains, central chains and other accessories for conveyor systems at its three locations Wickede, Sprockhövel and Fröndenberg.

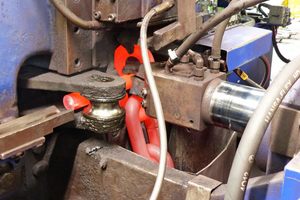

At Heko Ketten there is practically no series production, the company reacts flexibly to requirements and problems and mostly produces small lot sizes. All chains are adapted to the specific requirements of the customers’ conveyor systems. The specialist in hardening chains has equipped its production with seven modern multi-purpose vacuum chamber furnaces.

For Alexander Koch, the focus is on the customers and partnership-based cooperation. As a leading company in the market for round link chains for the cement industry, Heko manufactures quality chains “Made in Germany” for its globally operating customers, true to its corporate strategy. Commercial agencies in more than 50 countries guarantee fast on-site support. Two sales offices, one in Beijing/ China and one in Mumbai/India, serve the important Asian market.

Hardening shop at the heart: hard outside – soft inside

In 2017 the company celebrated its 100th anniversary. As with many other successful companies, it started small but full of ideas.

(He)rmann (Ko)ch, the founder and namesake of Heko Ketten, started out in 1917 as a 23-year-old blacksmith with a hand-operated forge for round link steel chains. Only five years later, the company was bursting at the seams and the many orders could no longer be fulfilled just by hand. With entrepreneurial courage and foresight, Koch invested in a new factory site, new production facilities and in the new technology of electrofusion welding. Another important basis for the success of Heko Ketten was a optimization of the hardening process over many years by Hermann Koch. After many trials, Koch built a tempering plant in 1939, which produced better results, and a hardening shop in 1943. Shortly after came the catastrophe: The tidal wave of the Möhnesee dam destroyed in the war flooded the production facilities, from the chain factory to the new hardening shop. But the Wickede company didn’t think of giving up – the production operation was rebuilt.

In the difficult times after the Second World War, it was once again the special hardening process that brought the company forward. The hardening process lengthened the service life of the chains. Key features of Heko hardened chains were an even surface hardness and a smooth transition from the hardened outer zone to the soft core.

From Wickede to the world

After the sudden and early death of Hermann Koch in 1955, his 26-year-old son Franz-Josef Koch took over the management of the company. The young company manager recognized early on that good and motivated employees are a key to success. His treatment of the company’s employees was the basis for the good reputation that Heko Ketten still has as an employer today.

Besides his social commitment, Franz-Josef Koch led the chain manufacturer into the world. In the 1950s, the company not only supplied the German steel industry, cement plants, machine engineering companies, coal and lignite mining operations and many other German companies were also among its customers. But Franz-Josef Koch wanted to expand further. Bit by bit, he increased exports and built up an international network of representatives.

In 1966, Franz Josef Koch invested in fully automatic chain welding machines – the era of hand forging was over. By 1970, Heko Ketten already had an export share of 50 % and introduced a new, successful product with chain wheels to the market, which extended the existing product range (chains for bucket elevators and other conveyor systems). In the 1980s, further investments followed, including new buildings and a fully automated bending and welding plant, and Koch opened up new markets. Waste incineration and sewage treatment plants joined the existing customers.

Koch died at the age of 62 in 1992, and for the second time a young man had to take over the fortunes of the family business overnight.

State ot the art

In 1992, Alexander Koch, a 26-year-old economics student, faced the challenge of leading his family’s legacy into the future. When he joined the company, in the anniversary year “75 years of Heko Ketten”, the company employed 100 people, generated around € 17 million in sales and supplied 75 % of its products for export.

In the economically difficult first years, Alexander Koch optimized processes, modernized production, reduced costs and established new partnerships, especially in Asia. The contacts to China as an emerging economic power were a clever move for the future development of Heko Ketten. With the introduction of the DIN ISO 9002 quality management system, a further basis for quality chains “Made in Germany” was created. With investment in a new welding shop, the flow of materials and working conditions were improved.

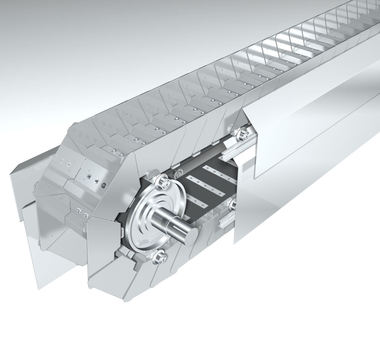

With the takeover of a competitor in the rotary kiln chains branch, the Fröndenberger Kettenfabrik Wilhelm Prünte, Koch moved the production of rotary kiln chains to this location and increased the export share. The heat-resistant ring chains are used in the cement rotary kiln at temperatures up to 1200°C. They improve the heat exchange, accelerate the material transport in the kiln, reduce dust emissions and clean the kiln wall. The ring chains for cement rotary kilns are not usually heat-treated but can be alloyed differently depending on the application and temperature zone in the rotary kiln.

The increasing demand for chains with long service lives led to the expansion and modernization of the hardening shop. In 2007, multi-purpose vacuum chamber furnaces with helium quenching were installed for several million euros and once again revolutionized chain hardening. The state-of-the-art technology not only improved the material properties, the hardening process is faster and more efficient. At the same time, Heko Ketten doubled the total capacity of the hardening shop and enabled processing of larger batch weights.

Committed and satisfied employees are also close to Alexander Koch’s heart. In 2013, the employees moved into a modern, new office building in Wickede. And, the company director in the third generation invested in further expansion. In 2014, Heko Ketten expanded its production area to a total of 40000 m² with the acquisition of the Kettenwerk Klein, a chain factory in Sprockhövel, and now employs around 125 people in the group. With the acquisition of the engineering company KoWey GmbH in Kamp-Lintfort in 2015, Heko acquired competence in the design of chains and accessories, bucket elevators, clinker conveyors and other equipment. Today, Heko can offer complete conveyor systems worldwide.

In the anniversary year “100 years of Heko Ketten” in 2017, an extension building for a new welding machine and modern break rooms for the staff was built for about € 2 million.

Environmental protection is an important issue for the chain supplier. For example, the office building is heated by a heat recovery system connected to the hardening furnaces. The proportion of plastic in the packaging area was reduced to a necessary minimum.

Let’s make a chain that does more than the competitor’s

Under this slogan Alexander Koch founded his own R&D department in 2015. The aim is to keep Heko as a chain supplier for bucket elevators and chain conveyors always at the cutting edge of technology. Together with universities, the company advances product developments in various research projects.

Today Heko Ketten supplies the cement industry worldwide, including, of course, the five biggest producers. In addition to the optimization of existing conveyor systems, the focus is on new business.

Today the company generates a turnover of € 32 million and 40 % of the products go to the cement industry, making the cement industry the most important customer sector. In addition, coal-fired power plants, the fertilizer industry and other sectors are supplied. The export share has meanwhile risen to 85 %, of which Asia accounts for about 40 %. In addition to China as a major sales market, Koch now wants to develop further markets, the last “white spots on our map”.

However, the chain manufacturer doesn’t just have its sights on its business. To mark its 100th anniversary, Heko Ketten has agreed to support a charitable project “SOS Bahini” in Nepal with € 100000. In this project, girls and women are supported in their own living groups to receive an education and later earn their living.

Satisfied employees are the best advertisement

Alexander Koch is sure of that. When he is asked whether there are any problems with recruiting new employees for the chain manufacturer, his answer is no – a very rarely heard answer in the industry. Motivated employees, a good environment, fair working conditions and flexible working hours ensure that there is a supply of interested young people from the surrounding area. Some employees are already in the second or third family generation at Heko and some spend their entire working life there.

Ready for new challenges

The great strength of his company is the willingness to seek solutions to problems together with the customers, emphasizes Alexander Koch. Added to this are short delivery times and high product quality “Made in Germany”. The chain manufacturer sees itself well prepared for the future. Whoever has successfully mastered 100 years, with all its ups and downs, will also be able to take on the challenges of the future, that is his motto. In the past, Heko Ketten has invested successfully. Today, the company is facing new challenges, especially digitalization. The first steps are the networking of production sites, and the monitoring of energy consumption and efficiency – others will certainly follow.