Mechanics of the grinding media in ball mills with longitudinal and transverse

motion of the grinding media

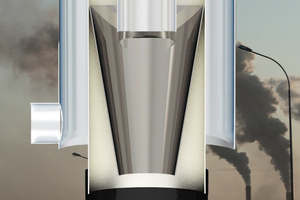

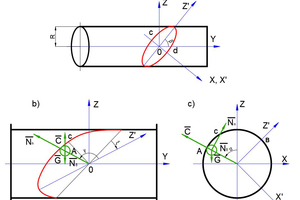

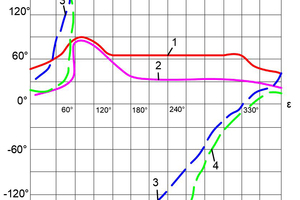

This article analyzes the problems of perfecting grinding equipment for large-scale production – cement, ore, coal. An improved design of a ball mill, equipped with internal energy exchange devices, is considered and there is a description of the technical and economic indicators of a standard and an improved mill. The method of calculating the kinematics of motion of grinding media in a mill with longitudinal and transverse motion of the grinding media is described and formulae for determining the effective forces are presented. Equations are given for determining the velocity regimes describing the motion of the grinding media.

1 Introduction

The production of many materials is associated with the need for fine grinding (down to a size of less than 100 µm) of the raw materials: cement, ceramic products, refractories, glass, ferrous and nonferrous metals, fertilizers, coal, etc. [1-3].

About 100 million t of raw materials and clinker are subjected to grinding just in the production of cement and 900 million t in the mining industry [4, 11].

The basic requirements for grinding equipment used in all sectors of the national economy can be formulated from the following general principles: large hourly productivity; lowest...