Method for cement production

(22) 02.02.2017

(43) 25.09.2018

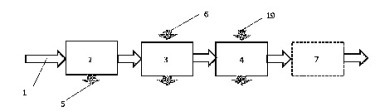

(57) Cement production method includes burning clinker in a furnace at the temperature 1450°C, cleaning from a dust with filtration in a filter of furnace gas containing CO2, SOx, NOx at the temperature 150-350°C, and emission into atmosphere with a chimney, joint grinding of received clinker and thermally treated in drying device at the temperature no more than 600-700°C a tuff and a gypsum; at that, the clinoptilolite is added as tuff including zeolitic tuff thermally treated in drying device with feeding furnace gas and at the time it is modified with cleaned from a dust with filtration in a filter with furnace gas containing CO2, SOx, NOx at the temperature 150-350°C.

(71) LEPL Shota Rustaveli National Science Foundation; LEPL Georgian Technical University (GE)