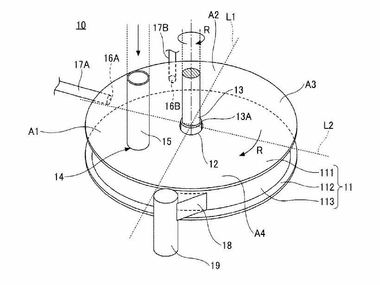

Method for manufacturing cement

(22) 28.05.2018

(43) 09.04.2020

(57) The present invention pertains to a method for manufacturing cement, wherein the gypsum is first calcined separately before being inter-grinded with the clinker so as to minimize the release of water of crystallization of during the inter-grinding stage. The method produces cement of high strength at all ages, better rheology, enables higher use of fly ash, and reduces CO2 emission during manufacturing.

(71) Ravi Kant Ahalawat, Faridabad (IN)