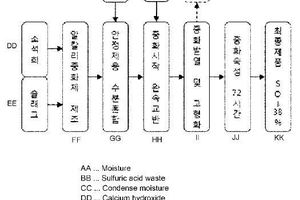

Method for preparing chemical gypsum having SO3 content of 38 % or greater (weight basis) by preparing alkali neutralizer using industrial byproducts containing steel slag or calcium oxide as major raw materials and neutralizing waste acid by dry method

(22) 29.05.2019

(43) 05.12.2019

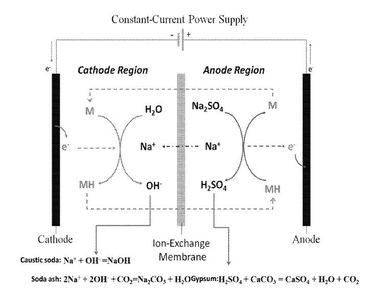

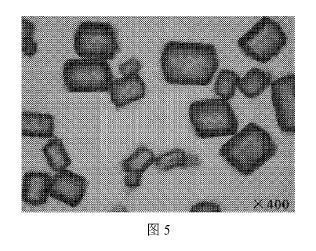

(57) The present invention relates to a method for preparing chemical gypsum having a SO3 content of 38 % or greater by preparing an alkali neutralizer using, as major raw materials, industrial byproducts containing steel slag or calcium oxide (CaO), and neutralizing sulfuric acid waste or sulfuric acid by a dry method. Firstly, as the recycling market of industrial byproducts such as steel slag expands, environmental problems with the disposal thereof can be solved. Secondly, it is possible to economically and stably dispose of the continuously increasing sulfuric acid waste in the semiconductor industry, and replace the generated byproducts with chemical gypsum, thereby expanding the recycling market. Thirdly, gypsum, which is used as a subsidiary material in cement companies and the like, is imported as natural gypsum due to the lack of domestic supply, and thus chemical gypsum can replace such imports and is economical because its price is cheaper than natural gypsum. Fourthly, due to the use of industrial byproducts as major raw materials, the price of an alkali neutralizer is cheaper than common liquid slaked lime and the like, and the process of dry neutralization is simple and economical. Fifthly, the method of the present invention is applicable, as required, to disposal methods of other acids such as hydrochloric acid, nitric acid and hydrofluoric acid, thus enabling economical disposal.

(71) Kest Co., Ltd, Chungcheongbuk-do (KR)