Millions in funding for Leipzig carbon-reinforced concrete research

Carbon-reinforced concrete can make an essential contribution to climate-friendly construction, because in contrast to the steel bar and mesh reinforced concrete commonly used to date, the new building material saves resources such as sand and cement and has a significantly better CO₂ balance. In addition, carbon-reinforced concrete offers many starting points for modern construction. For example, heating and electrical installations can be integrated into walls made of carbon-reinforced concrete. Scientists at the Leipzig University of Applied Sciences (HTWK Leipzig) are testing how such applications can be transferred to industry in two new research projects.

Multifunctional sample elements are to become industry standard

Sample elements made of carbon-reinforced concrete, which are connected to various thermal systems, are to be developed by an alliance of 15 partners from Saxony and Saxony-Anhalt as part of the “Industrial Standard Carbon-reinforced Concrete (ISC)” project. Among them is the Research and Transfer Center (FTZ) affiliated with HTWK Leipzig, which has been an important link between the university and regional industry since its foundation 25 years ago.

The FTZ scientists involved develop elements for integrated wall and panel heating systems. “For thermal systems to be integrated into building components, various prerequisites must be met. The electrical use of carbon is new and neither normed nor standardized. There is no experience in this regard, and this now needs to be explored in a wide variety of applications,” says Tilo Heimbold, electrical engineering professor at HTWK Leipzig and scientific director of the FTZ. In addition, the FTZ researchers are analyzing the energy balance and safety of all sample elements produced in the project, developing standardized and automated manufacturing processes for the components, testing their electromagnetic compatibility in the FTZ’s own EMC center, and compiling the findings in a set of technical rules.

The aim of the three-year research project is to develop an industry standard for semi-finished components made of carbon-reinforced concrete. This is intended to accelerate the transition to carbon-reinforced concrete construction. To implement this, the alliance has been receiving around € 8 million in funding from the German Federal Ministry of Education and Research since January 2022 under the “Rubin” innovation and structural change program. Around € 840000 are allocated to the FTZ.

Components with integrated data communication standard AS-Interface

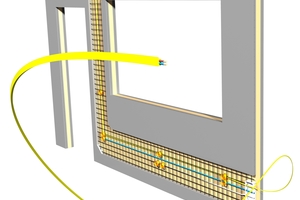

In another new research project, researchers at HTWK Leipzig are integrating electrical and data technology based on the industrial communication standard AS-Interface into carbon-reinforced concrete elements. Because houses made of carbon-reinforced concrete have very narrow walls, there is not much space left for the numerous installation cables that would otherwise be installed in them. Cables, cable ducts and control boxes should therefore be reduced already in the construction and installation phase.

“Through AS-Interface, numerous sensors and actuators communicate with each other via one and the same cable. They even draw their required power via this cable. This saves materials and makes the system extremely robust and fail-safe,” explains project manager Heimbold, who has helped develop AS-Interface for around 30 years. Today, the technology is used millions of times worldwide and enables automated processes in airports, factories and buildings. Heimbold: “AS-Interface is mainly used in industry. In our research project, we now want to make the benefits of the technology available for residential and office buildings as well.” Prefabricated members for an office wall are therefore to be produced as an example.

These will be manufactured in the new carbon-reinforced concrete pilot plant at HTWK Leipzig. Concrete construction professor Klaus Holschemacher explains: “We have been researching the new building material carbon-reinforced concrete for years. In our new experimental hall, we are demonstrating the fully automated production of carbon-reinforced concrete members on a model scale.”

For the “WallConnect” project, the German Federal Ministry of Economic Affairs and Energy is providing a total budget of around € 1.5 million from the “Lightweight Construction” technology transfer program until spring 2024. One third of this is being provided by HTWK Leipzig.