Numerical simulation of temperature field distribution in the kiln inlet system of a precalcining kiln

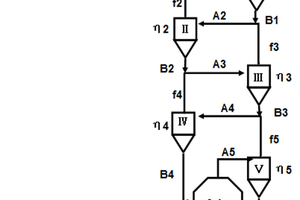

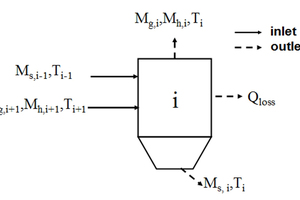

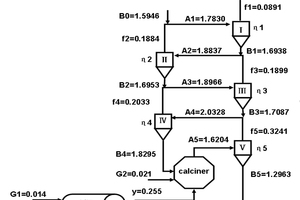

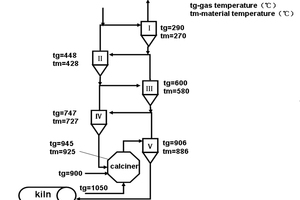

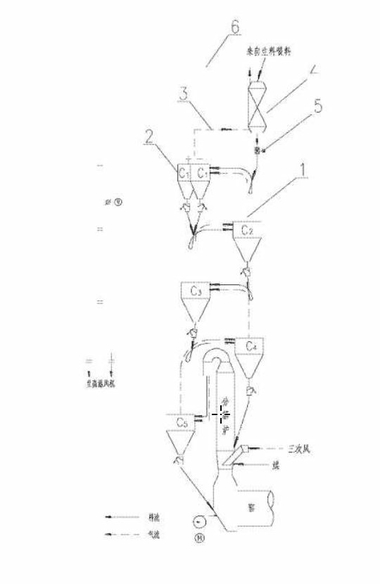

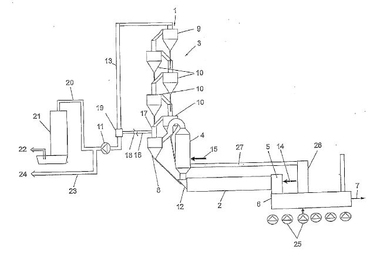

For the purposes of obtaining a high-performance clinker while reducing the requisite energy consumption, this paper investigates the temperature field distribution in a precalcining kiln and factors which affect such a temperature field distribution. Based on the solid material balance calculation of four-level precalcining kiln systems, the solid material balance and distribution of the Five Level Preheater + Calciner process (FLPC) were established. Then, the heat balance calcination model was established. The results of numerical simulation of the precalcining kiln were found to closely reflect the actual situation. The separation efficiency of the cyclone, the ratio of calciner coal feed, the temperature of the tertiary air and the surface heat loss all affect the temperature field distribution in the kiln inlet system of a precalcining kiln.

1 Introduction

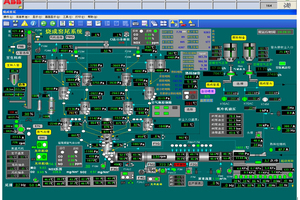

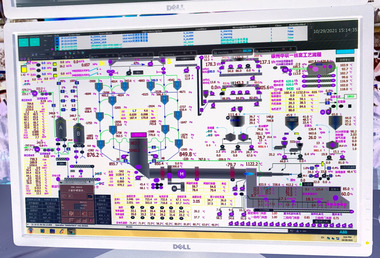

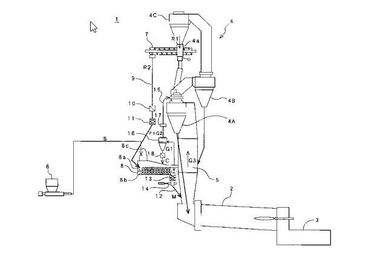

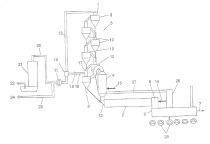

A precalcining kiln is a series of equipment items for producing cement clinkers. The raw material for cement production is a mixture of predetermined proportions of limestone, silica and small quantities of alumina and iron oxide. The raw material passes sequentially through a preheater, a calciner, a kiln and a cooler to produce cement clinkers. In the preheater section, the raw material is preheated to calcination temperature via heat exchange with hot gases from the calciner. In the calciner, most of the raw material is calcined. The energy required for an endothermic...