Packaging cement – the sustainable way

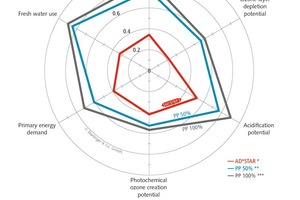

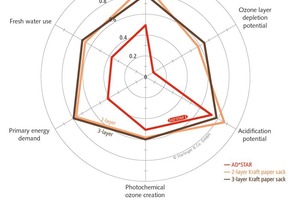

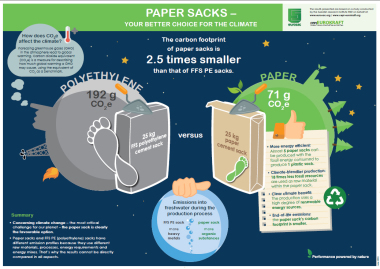

Cement packaging is a significant factor for cement producers and sellers regarding product protection, shelf appearance, cost margins, and sustainability targets. An independent study compared the environmental impact of paper cement sacks, sewn cement sacks made of recycled polypropylene tape fabric, and hot-air welded AD*STAR cement sacks made of coated polypropylene tape fabric.

The Life Cycle Assessment (LCA), carried out by the German PE International AG (now thinkstep AG) and commissioned by the Austrian machinery supplier Starlinger & Co. Ges.m.b.H., compared sewn sacks made in China and kraft paper sacks made in Saudi Arabia with AD*STAR sacks which were produced in both countries respectively. In the course of the study the entire life cycle of the cement sacks, i.e. from sack production and transport to the cement plant, the use phase of the sacks, to their end-of-life phase, was reviewed. All analysed sacks had a filling capacity of 50 kg cement (see Table 1).

...