Patented conveyor belt cleaner designed to reduce total ownership cost

A significant investment by Martin Engineering in tooling and product engineering in bulk material handling technology has produced a patented conveyor belt cleaner that is projected to reduce the cost of ownership by cleaning better and lasting longer. A lower purchase price was also one of the primary goals in designing the Martin QB1 Cleaner HD, achieved by adopting state-of-the-art roll forming equipment as part of Martin Engineering’s manufacturing capabil-ities. The move is part of an overall plan to deliver high-performance components at industry-best prices.

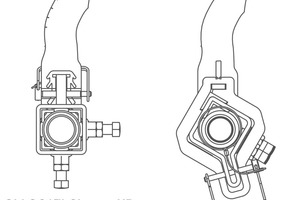

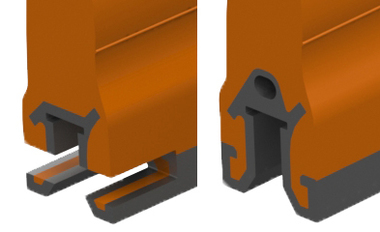

Described as one of the most comprehensive patents the company has ever been awarded, protection covers the main frame design, manufacturing process and attachment method. The new cleaner features Martin Engineering’s “CARP” (Constant Angle Radial Pressure) technology to maintain the most efficient cleaning angle throughout service life, with a no-tool replacement process that can be performed safely by one person in less than five minutes. It delivers outstanding performance and durability, while reducing the total cost of ownership.

The new design also features a special alignment system to facilitate extremely precise installation.

The product announcement comes on the heels of Martin Engineering’s introduction of the company’s “Forever Guarantee”, which ensures lifetime no-cost replacement of tensioners and main frames for any belt cleaner assemblies that are exclusively fitted with the company’s replacement blades. The Martin QB1 Cleaner HD can be retrofitted onto any existing Martin Engineering tensioners, as well as most competitive systems.

In addition to its cost advantages, the QB1 HD design features a square mainframe positioned to shed dust and spillage. The urethane blade formulation can accommodate belt speeds of up to 4.6 m/sec and service temperatures of -40° to 70 °C. The QB1 HD is available in lengths of 457 to 2438 mm and can also be ordered in 3.05 m sections, allowing distributors or customers to cut to length for increased versatility.

//www.martin-eng.com" target="_blank" >www.martin-eng.com:www.martin-eng.com