Pre-processing hazardous waste

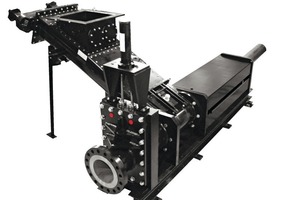

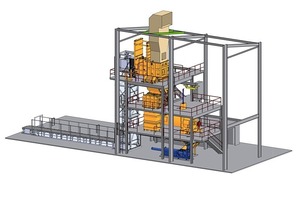

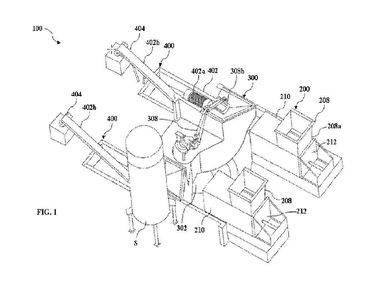

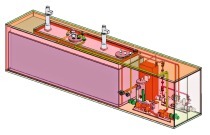

The SID Group is known as a supplier of shredding equipment and also works in the conception, design, and manufacturing of complete pretreatment and homogenization units for hazardous waste. This Shredding-Mixing-Pumping system SID successfully transposed from hazardous waste incineration into the cement industry for the preparation and injection of alternative fuel (AF).

1 Introduction

The first SMP installation for the cement industry was delivered in 2005 to the BBMG Beijing cement plant, China. Up to now SID received several additional contracts for the delivery of similar SMP plants. The latest SMP installation was put into operation in March 2014 in one of China’s biggest cement plants from Hongshi.

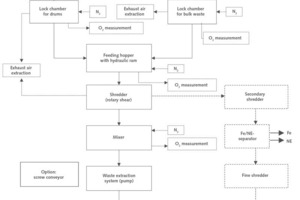

Since the commissioning of the first pretreatment installation at BBMG, the cement manufacturer benefits from the advantages of this proved technology for the incineration of its alternative fuel. All pretreatment and homogenization units are composed of three...