Predictive maintenance

More and more plant operators are coming to rely on predictive maintenance. Maintenance scheduling can be optimized with the help of asset condition monitoring and innovative software solutions.

The Swiss company Cassantec AG, with secondary headquarters in Berlin, presents a prognostic solution for equipment malfunctions. Cassantec Prognostics, as the algorithm is called, provides the time component for predictive maintenance: With this tool, a company can predict when an asset is most likely to malfunction.

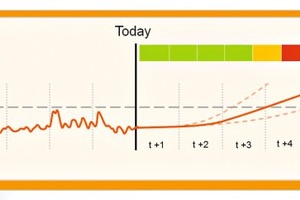

Many branches of industry are now working on “predictive maintenance” initiatives. Digital networking of assets makes it possible to permanently monitor condition data and, with the help of software solutions like Cassantec Prognostics, to process them appropriately. With the aid of condition-based availability forecasts, users optimize their own asset management practices and gain risk profiles of future malfunctions. “Appropriately adjusted maintenance schedules do away with unnecessary costs,” explains Cassantec AG CEO Moritz von Plate. “For example, when parts are not replaced according to a fixed timetable, but only when their condition calls for it. So, Cassantec Prognostics users are able to avoid unnecessary asset downtime. The active management of residual asset service life yields major benefits for the company. By means of a traffic light system, our software shows the user when a malfunction can be expected.”

Corresponding prognostic reports can be drawn up for time spans of months or even years.

Predictive maintenance is the key

The targeted use of predictive maintenance generates major savings potential with regard both to planned repairs and to maintenance outlays in comparison with unplanned repairs. It also reduces downtime and maintenance time expenditures while decreasing service costs, accelerating the production flow and increasing productivity. As von Plate knows, “The overall potential for further sophistication is nowhere near exhausted, and machine learning technology is already contributing to further improvement.”

//www.cassantec.com" target="_blank" >www.cassantec.com:www.cassantec.com