Predictive maintenance reduces

downtimes and maintenance costs

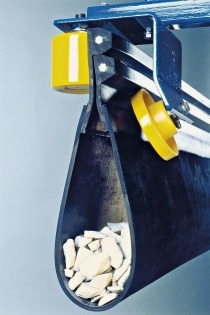

Whether in open-pit or underground mining, for steep inclines or across distances spanning kilometers – conveyor belts are the core component of many industrial sectors. In harsh operating conditions, they transport loads weighing several tons not to mention sharp, hot, oily and greasy goods. Smooth running of these belts is crucial for cost efficiency. If the belt system experiences an extended downtime, the entire production chain frequently collapses. This in turn results in considerable sales losses for the operators. To allow conveyor belt systems to run free of faults and...