Process air with system

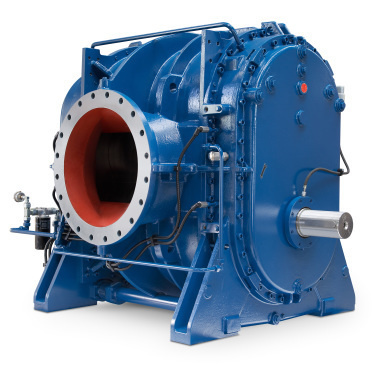

Aerzen now offers a wider range of process air stages by introducing the innovative large blower series “Alpha Blower”. Aerzen large blowers are positive displacement blowers which can be applied virtually anywhere, convincing users worldwide by their quality, reliability and performance. These blowers reach volume flows of up to 77 000 m³/h at a maximum overpressure of 1000 mbar and a maximum negative pressure of -800 mbar. This blower series is ideal for demanding ranges and applications. These blowers are used for the production of gases and oxygen or in the cement industry.

With the Alpha Blower Aerzen want to raise the proven concept to a new level of efficiency and flexibility. This increases the variety of models of Alpha Blower to 104 variants in total. The Alpha Blower proves to be particularly innovative with regard to measures for reducing pipe sound emissions.

System optimisation due to process monitoring

By means of its communicative control system, AERtronic, Aerzen has been offering the possibility to integrate process air packages into the production interfaces of our customers for a long time. Furthermore, the control system can be extended by the module WebView so that operating or service data are retrievable at any time and from any point in the world. Warning or error messages of the blowers or compressors are transferred immediately by email to the relevant sections. Potential malfunctions can be detected early enough to initiate countermeasures promptly. A big step in the direction of lasting process reliability!

//www.aerzen.com" target="_blank" >www.aerzen.com:www.aerzen.com