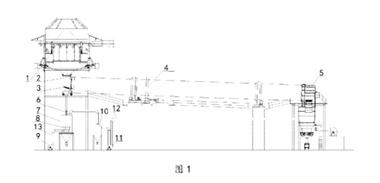

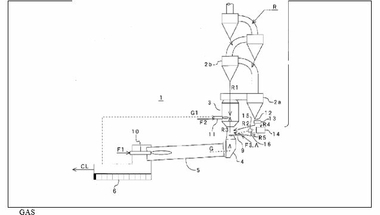

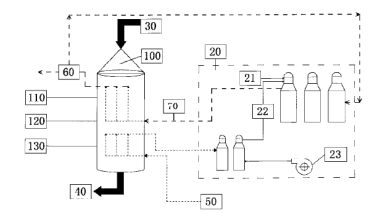

Process and system for reducing ringing in lime kilns

(22) 20.09.2018

(43) 27.03.2019

(57) This application discloses exemplary processes and systems for reducing mineral ring accumulation in calcination kiln. The processes and systems comprise inserting non-condensable gases (“NCGs”) in a preheating zone of a calcination kiln, upstream of the burner end. The pre-heating zone may be characterized by temperatures ranging from 1300° F to 1750° F. The system may desirably comprise a plenum for inserting the NCGs into the rotating calcination kiln at the pre-heating zone.

(71) Andritz Inc (US)