Roller press

(22) 04.02.2014

(43) 07.08.2014

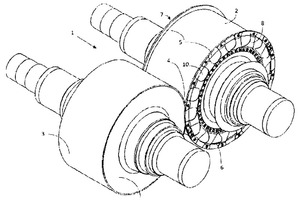

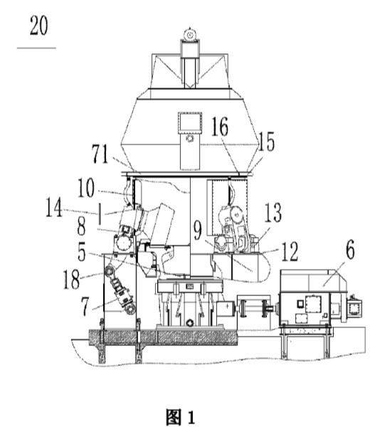

(57) A roller press (1) is described for grinding of particulate material such as cement raw materials, cement clinker and similar materials, which roller press (1) comprises two oppositely rotating rollers (2, 3) forming between them a roller gap (4) and a co-rotating annular disc (5), which in concentric manner is attached to an end surface (6, 7) of one of the rollers (2) by means of a number of resilient attachment elements (8) and being movable in the direction of the roller axis, where the outer diameter of said annular disc (5) is greater than the diameter of said one of the rollers (2), hence the annular disc (5) in the area of the roller gap (4) extends toward the other roller (3), thus covering at least part of the roller gap (4). The roller press (1) is peculiar in that the inner diameter of the annular disc (5) is smaller than the diameter of the roller (2), to which it is attached, thus overlapping the end surface (6, 7) of said roller (2), and that the resilient attachment elements (8) are evenly distributed over the circumference of the annular disc (5) and provided with spaces or openings (19) there between. It is hereby obtained that the annular disc (5) does not get stuck by material to be grinded or destructive forces damaging construction parts are not accumulated. This is due to the fact that material in the roller press (1) according to the invention is allowed to escape from the area between the annular disc (5) and the roller (2) to which it is attached.

(71) FLSmidth A/S, Vigerslev Allé 77, 2500 Valby (DK)

(84) ARIPO (BW GH GM KE LR LS MW MZ NA RW SD SL SZ TZ UG ZM ZW), Eurasian (AM AZ BY KG KZ RU TJ TM), European (AL AT BE BG CH CY CZ DE DK EE ES FI FR GB GR HR HU IE IS IT LT LU LV MC MK MT NL NO PL PT RO RS SE SI SK SM TR), OAPI (BF BJ CF CG CI CM GA GN GQ GW KM ML MR NE SN TD TG)