Solidification of simulated borate liquid wastes with alkali-activated slag cements

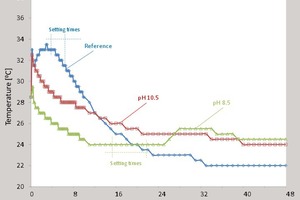

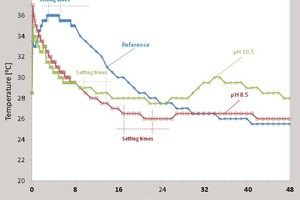

The solidification of borate solutions with alkali-activated slag cements (AASC) was studied. The results showed that AASC activated with 7.5% NaOH had acceptable setting times, and that the compressive strength of the solidified waste after curing for 28 d varied between 26 and 30 MPa, depending on both the concentration (60 – 240 g/l) and the pH value (8.5 – 10.5) of the associated borate solution. Increasing the concentration of the borate solution and lowering the pH resulted in a reduced rate of setting of the fresh AASC paste, retardation in the structural formation of the hardened AASC paste, a reduced degree of hydration, and suppression of the formation of C-(A)-S-H. Parameters such as setting times, development of compressive strength, and waste loading can be influenced by the NaOH/H3BO3 ratio, which must be ≥ 1.

1 Introduction

Operational and decommissioning activities in different nuclear facilities generate large volumes of various types of radioactive waste (RW) streams [26], which are categorized as gaseous, liquid, dry solids or wet solids, depending on their physical state [1, 45]. Boric acid (H3BO3) is one of the most common types of liquid waste concentrate generated by pressurized water reactors. Boric acid waste is first neutralized using sodium hydroxide, then concentrated via evaporation. The resulting borate slurry is usually immobilized in cement, polymers, or bitumen [14, 20, 24]....