Substantial gain in cement mill output with minor investment – a case study

1 Introduction

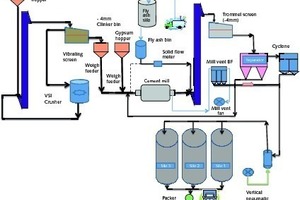

The manufacturing process of cement is a highly electrical energy intensive process. Size reduction in a plant consumes 55-65 % of the total electrical energy consumption accounting for 30-40 % of the total production costs. So, a ball mill used for cement production consumes nearly 30-35 % of total power consumption of the plant. Hence the impact of ball mill productivity enhancement has substantial influence on manufacturing cost reduction.

In our group, the ball mill output ranges from as low as 52 tph to as high as 290 tph with power consumption ranging from as low as...