The Pneumo-Deflector

For the last two decades Unitherm Cemcon has implemented several tools in the burner to influence the distribution of solid recovered fuel (SRF) particles in the flame. For the total use of the combustion energy of the SRF, the residence time of the particles in the flame has to be maximized. This cannot be achieved by increasing the velocity of the SRF, but by changing the injection angle.

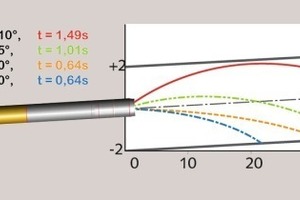

According to the experience gathered from numerous of Mono Airduct System (M.A.S.) burner installations, an increase of the injection speed will not increase the retention time. Whereas a change of the injection angle by 5° will theoretically extend the trajectory and increases the available time for combustion in the flame by approx. 60 % (Fig. 1).

Due to the abrasive property of solid recovered fuel, a mechanical deflection of the particles is difficult to implement. Therefore Unitherm invented the Pneumo-Deflector. As the name suggests, the deflection of the particles is done pneumatically. Therefore a certain amount of air is led to the business end of the fuel pipe. This allows deflection of the SRF particles in an unprecedented way.

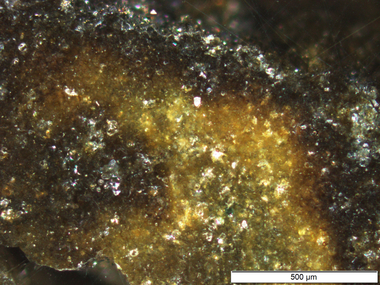

The combination of variable exit speed and angle allows any setting for optimum operation with alternative fuels. The operation of the new device can be adjusted for varying fuel qualities (Fig. 2). Results of installations with the deflector show an essential increase in the thermal substitution rate (TSR) with constant clinker quality.

The Pneumo-Deflector can be found in all new M.A.S. burners. Also existing burners for alternative fuels can be retrofitted with this patented system.

//www.unitherm.co.at" target="_blank" >www.unitherm.co.at:www.unitherm.co.at