Thermal behaviour of a coarse raw mix and the micro-homogeneity of the resultant clinker

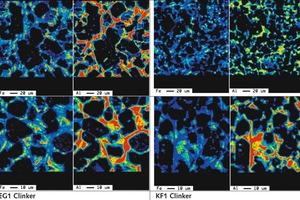

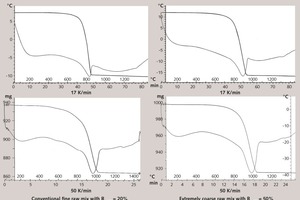

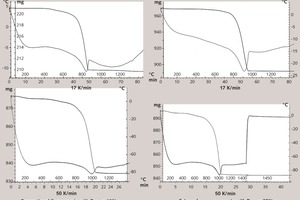

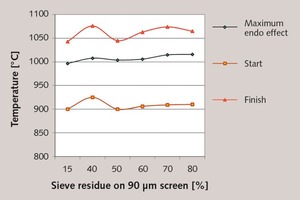

Clinker produced from a coarse raw mix displays a more homogeneous distribution of intermediate phase and a less uniform C3 A/C6AxFy ratio than clinker made from a conventional fine-grain mix. The more pronouncedly variable C3 A/C6AxFy ratio indicates the formation of two SiO2- and Al2O3-Fe2O3-rich melts, out of which the subject intermediate phases precipitate on completion of alite formation. Subjected to rapid heating (50 K/min) the coarse raw mix is seen to have a significantly lower calcite calcination temperature than that of the conventional fine mix.

1 Clinker micro-homogeneity

1.1 Introduction

A lack of micro-homogeneity and inadequate sinterability on the part of a given raw mix is generally attributable to an insufficient degree of fineness [1]. Clinker produced from such a mix therefore may also display deficient micro-homogeneity.

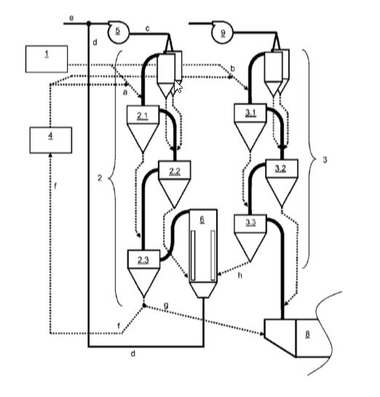

Despite the fact that the precipitation time of the raw mix in a cyclone heat exchanger accelerates with the square of the particle diameter, no appreciable segregation of the raw mix results, because the material is subsequently remixed in the ascending and descending downstream pipes and, in particular in...