Unveiling the “invisible”

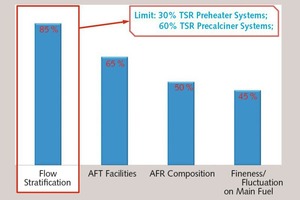

AFR co-processing limitations

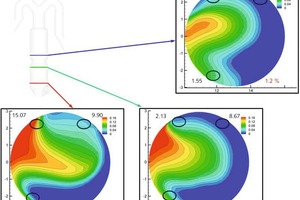

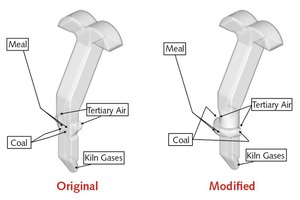

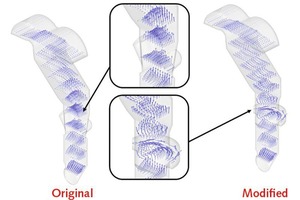

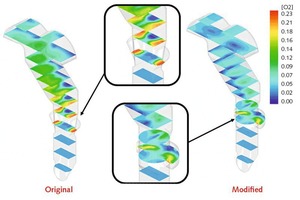

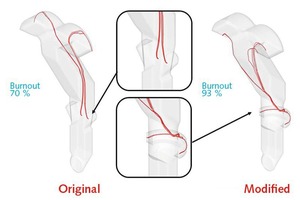

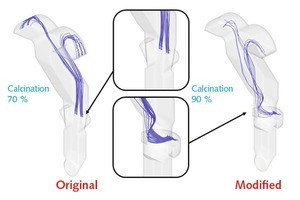

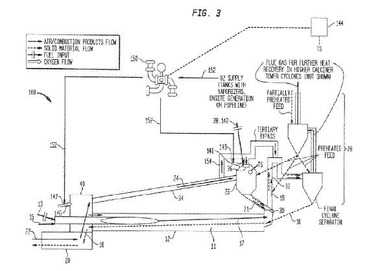

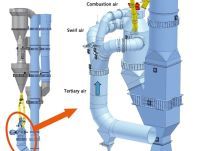

Most cement plants have limitations in terms of co-processing due to flow stratification leading to lower fuel burnout/calcination, high CO/NOx and build-ups. The identification of flow stratification is extremely difficult and requires elaborate in-flame and 3-D mapping of the temperature and major gas species to quantify the air-fuel mixing pattern and mixedness levels. In this paper, a mineral interactive computational fluid dynamics (MI-CFD) model encompassing combustion and mineral interactions is used to visualise intricacies of calciner internal aerodynamics and its effect on meal calcination levels and fuel burnout. Modelling results provide a cost-effective way to reduce flow stratification, which leads to the implementation of low-cost solutions.

1 Introduction

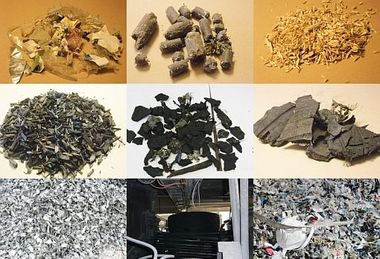

The use of alternative fuels and raw materials have become an undeniable reality in the cement industry worldwide, motivated by ever increasing fuel costs as well as environment-efficient solutions. Under the name “co-processing”, the use of these unconventional materials in the cement manufacturing process with the purpose of energy and/or resource recovery combine the safe disposal of these residues with economic savings of the reduction in the use of conventional fuels and raw materials through substitution. The alternative fuels therefore are regularly “co-processed”, but not...