Use of natural heavy mineral sands

for increasing the gross dry density

of calcium silicate units

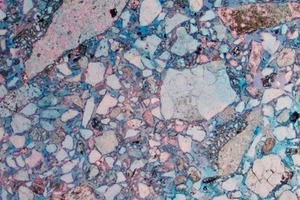

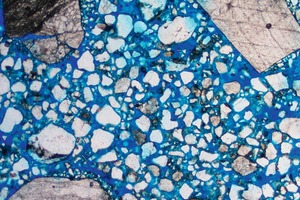

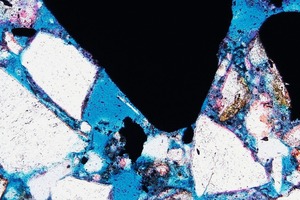

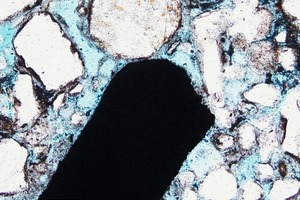

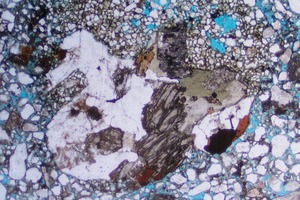

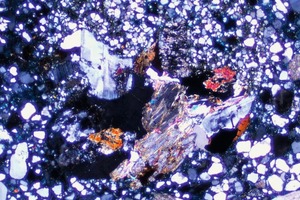

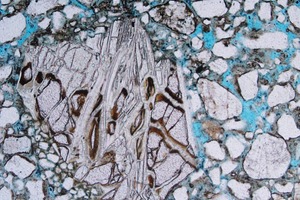

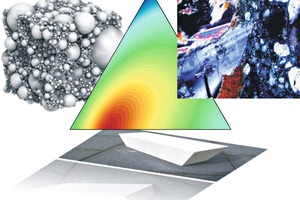

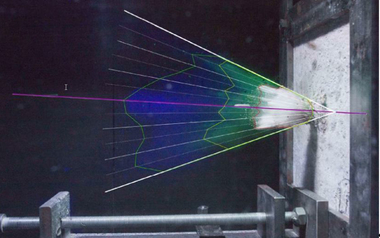

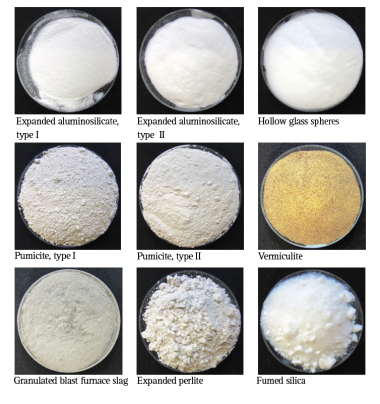

This AiF project enabled experimental demonstration of the fact that natural, heavy mineral sands can be used as raw material for calcium silicate unit specials of very high gross dry density. The products in question are exclusively intended either for satisfying very stringent sound insulation requirements or for radiation shielding purposes.

1 Introduction

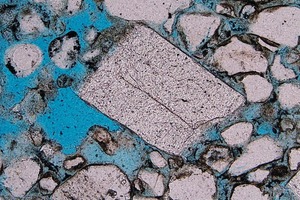

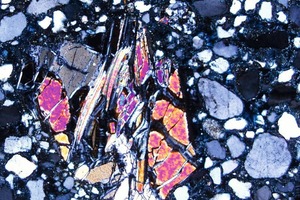

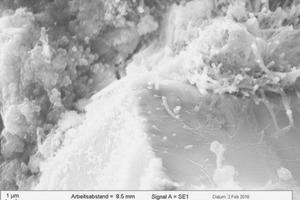

Commercial-grade calcium silicate units are produced from lime, natural mineral aggregates and water in a process called hydrothermal curing. Also referred to as steam curing, the process combines partially dissolved mineral-aggregate silica and the available hydrated lime calcium-silicate hydrate (CSH) phases that solidify the sand to a level of strength also defined by their grain-to-grain contact forces. Modern construction requires building bricks of high gross dry density for acoustic insulation purposes, and conventional calcium silicate unit products serve that purpose...