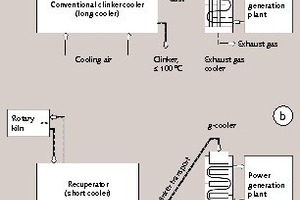

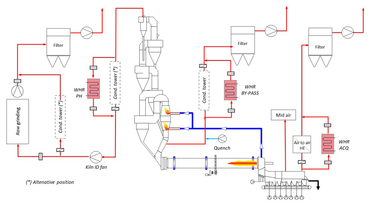

Use of the CP g-cooler in waste heat recovery systems

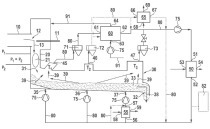

This article discusses the possibility of improving the utilization of waste heat from a clinker cooler for power generation by use of a g-cooler with upstream recuperator. The g-cooler is a moving bed reactor with indirect heat dissipation. Up to now, this cooler has always been operated with cooling air. With a view to achieving more efficient heat extraction, an analysis was carried out to assess the suitability of a g-cooler utilizing heat transfer oil as the coolant and evaluate the consequences.

1 Introduction

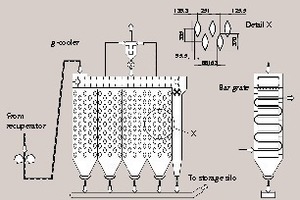

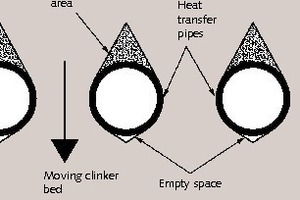

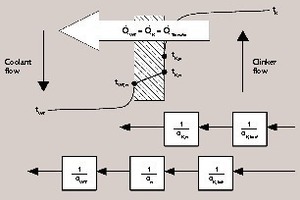

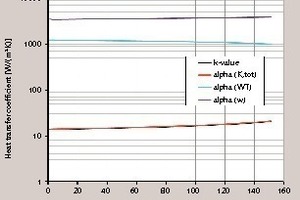

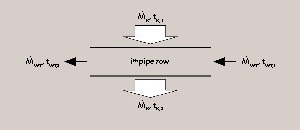

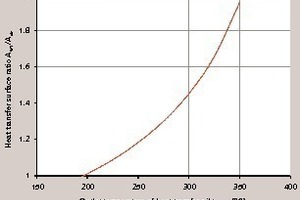

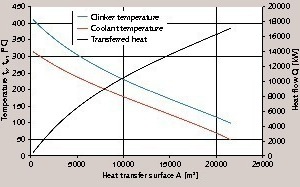

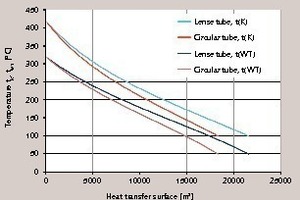

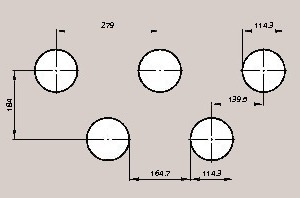

The Claudius Peters g-cooler is a moving bed reactor for indirect cooling of free-flowing bulk materials. The thermal content of the bulk material is transferred to a coolant flowing through a pipe bundle with specially shaped and arranged pipes. Originally, the g-cooler has been developed for cooling cement clinker down from tK,in ~= 400°C to tK,out ≤ 100°C using air as the cooling medium. For this purpose, a short grate cooler/recuperator is installed downstream of the rotary kiln, to cool the clinker down from the kiln outlet temperature of tK,kiln ~= 1350°C to approx. tK,in,...