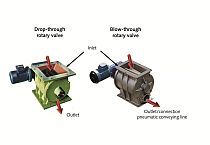

Wear-protected rotary valve for 60 t/h dry lignite

From the outset, this application has demonstrated the advantages of a rotary valve over screw pumps that are normally used for feeding. So the rotary valve does not constitute a potential igniting source, as the circumferential speed at the normal operating rate is below 1 m/sec. The valve is also available in a flame resistant version. With an operating power requirement of only 4 kW tremendous electrical power savings are possible. Simple maintenance and long maintenance intervals lower operating costs even further. Due to its lightweight design and low operating speeds the valve only requires a compact, simple foundation. These features also result in lower noise emissions.