thyssenkrupp to modernize Secil cement plant in Portugal

Secil Group, a major Portuguese cement producer and provider of construction materials, has entrusted thyssenkrupp Industrial Solutions S.A.S. (France) with the modernization project of its Outão cement plant, one of the three cement plants operated by Secil in Portugal.

The existing production line, established at the beginning of the 20th century, is located south of Lisbon on the peninsula of Setùbal. With an annual production capacity of around 2 million t, it is one of the largest cement plants in Portugal. The Outão facility includes a private maritime quay that allows annual exports of almost 1.5 million t of cement and clinker by sea to more than 20 countries.

Secil implements the R&D Project “CCL – Clean Cement Line” at its Outão cement works in Portugal. The CCL Project aims to bring the plant to the forefront of energy efficiency, low NOx and lowest CO2 emissions among the European cement producers. The CCL Project is partly funded by the Portugal 2020 Government incentives program.

Samir Abi Ramia, CEO of thyssenkrupp Industrial Solutions France: “This project marks a milestone for our Grey2Green initiative and is proof of the rising demand for green technologies in the cement industry. Secil is aware of the stakes of tomorrow and beyond and places great value on sustainability. With our energy-saving and emission reducing technologies we are proud to play our part in the transition towards a carbon neutral cement production.”

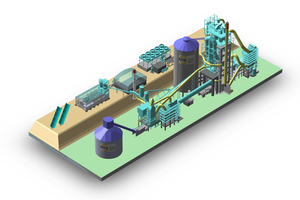

thyssenkrupp’s scope consists of the modification of the existing rotary kiln and preheater tower, which includes several new developments to provide a highly customized solution to Secil. The installation of a new AS-MSC calciner equipped with a prepol® SC-S calcining system will increase fuel flexibility and maximize the use of a wide range of alternative fuels, with a minimum substitution rate of 85%. A new polytrack® 7T/5-3R grate cooler, including a new cooler dedusting system, will replace the existing planetary cooler. These modifications will contribute to eliminate the dependence on fossil fuels and promote the development of low carbon clinker and cements. Secil expects that, with this investment, its plant will rank among the top 10% of the most efficient cement plants in Europe.