REFERENCES

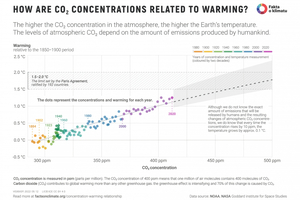

[1] Stips, A., Macias, D., Coughlan, C, Garcia-Gorriz, E, San. Liang, X.: On the causal structure between CO2 and global temperature. Sci Rep 6, 21691 (2016). https://doi.org/10.1038/srep21691

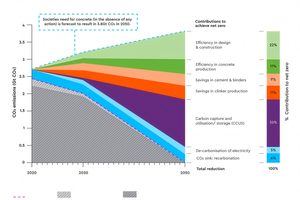

[4] Jiaomei, M., Jiachen, L., Dongren, D.; Huanying, Y.: New version of GB16780 brings challenge and opportunity for Chinese cement industry. ZKG 7 (2022), p. 34-41

[5] Decker, H.: Durchbruch für den CO2 Staubsauger, Frankfurter Allgemeine Zeitung, Nr. 140, June 20, 2025, p. 18

[6] Edwards, P., Harder, J.: CCUS Projects: A Reality Check. Global Cem. Mag., July-August 2025, p. 8-10

[7] Fleiger, K.; Hoenig, V.; Schneider, M.: Oxyfuel for cement industry decarbonization. Int. Cem. Rev. 2024, No 3, p. 42-45

[8] Jamali, A., Fleiger, K., Hoenig, V. Ruppert, J.: Modelling and optimisation of the oxyfuel clinker burning process, Cement Int. 16 (2018) Nr. 5, p. 44-47

[9] Schneider, M.; Puntke, S.; Spanka, G.: Auswirkungen des Abfalleinsatzes in der Zementindustrie auf die Produktqualität. Thermische Industrie- und Gewerbeabfallentsorgung: Stand und Entwicklung; Tagungsband 13. Aachener Kolloquium Abfallwirtschaft, Nov. 2000. Dohmann, M. (ed.). Aachen: RWTH Aachen, Inst. f. Siedlungswasserwirtschaft, 2000. - (Abfall-Recycling-Altlasten 22). - ISBN 3-932590-65-1, p. 8/1-8/12

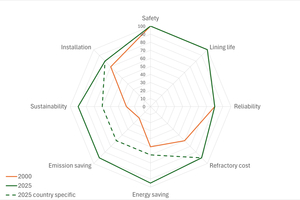

[10] Klischat, H.-J., Zielinski, U.: Key Aspects for Refractory Performance in Waste Fuel Operated Cement Kilns, 6th International VDZ Congress 2009, September 30 to October 2, Düsseldorf 2009

[11] Klischat, H.-J., Södje, J.: Magnesia, an essential Raw Material for Cement Kiln Refractories, refractories worldforum 4 (2012) Nr. 2, p. 77-84

[13] Rowland, J.: Refractories and the Sustainability Challenge. Cement Products July August 2024, p. 28-35

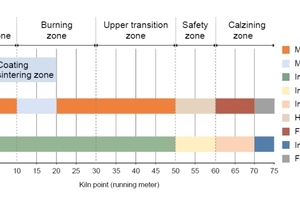

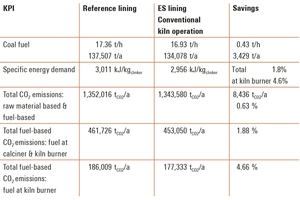

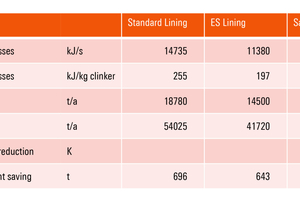

[14] Klischat, H.-J., Wirsing, H., Groger, P., Puntke, S.: Effective CO2-Reduction for Rotary Kiln Burning Process by using Energy Efficient Linings; UNITECR 2023, Frankfurt, Proceedings p. 554-557

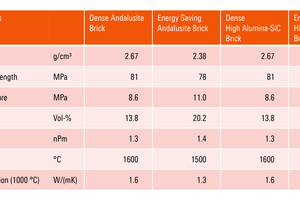

[15] Akkasoglu, U., Sarioglu, N., Ufuk, N.: Energy-Saving Refractory Bricks for Sustainable Lining of Rotary Kilns, UNITECR 2023, Frankfurt, Proceedings p. 558-560

[16] Bartha, P.; Hotz, G.: Einsatz und Bewährung wärmedämmender feuerfester Auskleidungen in Drehofenanlagen der Zement-industrie (Use and performance of insulating refractory linings in the cement industry). Ber. Dt. Keram. Ges. 52 (1975) Nr. 5

[17] EP 2883853B1, Coarse ceramic fire resistant product and method for its manufacture and its use, Refratechnik Holding GmbH, 21.10.2014

[18] Klischat, H.-J., Puntke, S., Groger, P., Wirsing, H.: Sustainable Linings for Rotary Kilns, UNITECR 2022, Chicago, Proceedings Downloadable from bulletin-archive.ceramics.org

[19] Schäfer, S.; Fleiger, K.: Independent expert evaluation based on a simulation study of a novel refractory brick used in the cement clinker burning process of a rotary kiln; VDZ Technical Report No. A-2015/0657, March 2015, Düsseldorf, Germany

[20] Fleiger, K.; Joschko, D.: Independent expert evaluation on improvement of carbon footprint and energy usage by refractory technology; VDZ Technical Report No. A-2022/0921, March 2023, Düsseldorf, Germany

[21] European Cement Research Academy, Ed. The ECRA Technology Papers 2022 - State of the Art Cement Manufacturing - Current Technologies and their Future Development. Duesseldorf, 2022. Available at: https://ecra-online.org/research/technology-papers