REFERENCES

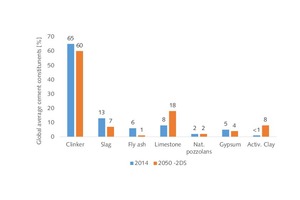

[1] IEA (International Energy Agency): Technology Roadmap, Low-Carbon Transition in the Cement Industry. International Energy Agency, April 2018, Paris/France

[2] Cembureau: Cementing the European Green Deal - Reaching Climate Neutrality along the Cement and Concrete Value Chain by 2050, May 2020, Cembureau The European Cement Association, Brussels/Belgium

[3] Harder, J.: Demand and Availability of Raw Materials for the Cement and Concrete Production, Presentation at ECRA Online Seminar OS20-03, 30th September 2020

[4] Antoni, M. et. al.: Cement Substitution by Blends of Metakaolin and Limestone. Cement and Concrete Research, 42 (2012), p. 1579-1589

[5] Scrivener, K.L.; John, V.M.; Gartner, E.M.: Eco-efficient cements: Potential, economically viable solutions for a low-CO2, cement-based materials industry. United Nations Environment Programme (UNEP), 2016, Paris/France

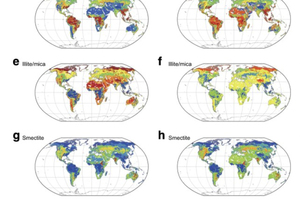

[6] Akihiko, I. et. al.: Global distribution of clay-size minerals on land surface for biogeochemical and climatological studies. Scientific data, Springer Nature, Aug 22, 2017

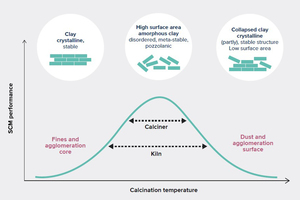

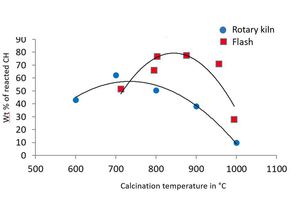

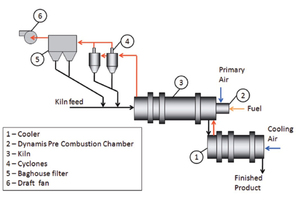

[7] Canut, M. et. al.: Calcined clay - Process Impact on the Reactivity and Colour. Proceedings of the 3rd International Conference on Calcined Clays for Sustainable Concrete, 15.10.2019-17.10.2019, New Delhi/India, Volume I, pp. 155-168

[8] Enders, M., Teutenberg, R., Sandberg, P.: Automated calorimetry – the missing link in quality control. ICR, June 2020

[9] Martinez, R.: Report on the contribution to the standardization system regarding FISSAC products. WP 3 – Product Eco-Design and Certification, Task 3.4 Standardisation of Products, Subtask 3.4.1 & 3.4.2, Ref. Ares (2020) 1270499 – 28/02/2020