Application of medium temperature SCR in the cement industry

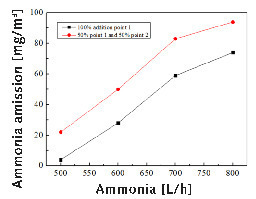

With the improvement of environmental protection standards, the emission standard of nitrogen oxides of cement plants in many provinces of China has been limited to 100 or 50 mg/m3, and the emission standard of ammonia has also reached 8 mg/m3 (even 5 mg/m3). In the past two years, Chinese cement enterprises began to install SCR systems, including high temperature SCR and medium temperature SCR. The author analyzes the denitration effect of medium temperature SCR and its influence on ammonia emission concentration in a 5000 t/d clinker line. Chinese cement plants are facing increasingly stringent environmental standards. Ultra-low emission standard of air pollutants for the cement industry [1] demands that NOx emission concentration is lower than 100 mg/m3 and ammonia slip is lower than 8 mg/m3. Many provinces have even stricter requirements which are NOx ≤ 50 mg/m3 and NH3 ≤ 5 mg/m3. In order to meet the emission standards, Chinese cement enterprises are trying many new denitration technologies, such as high temperature SCR, medium temperature SCR, LCR, etc. Only in 2021, Chinese cement enterprises have built 41 SCR denitration systems. The author analyzed the prospect of medium temperature SCR technology in the cement industry by introducing a 5000 t/d clinker line with medium temperature SCR.

1 Medium temperature SCR in the cement industry

1.1 SCR catalyst

SCR catalysts in the cement industry are generally divided into three types according to different temperatures: high temperature SCR catalyst, medium temperature SCR catalyst and low temperature SCR catalyst. The scope of high, medium and low temperature is not the same as that in the power industry, which is due to the characteristics of the cement industry itself. The working temperature range of high-temperature SCR catalyst in the cement industry is 280-350 °C, which is arranged between the outlet of cyclone one and the waste...