Black Capture & Kalkwerke Oetelshofen: Working together towards an emission-free lime industry

In many industrial sectors, every effort is currently being made to pave the way for CO2 neutrality by 2035. While process-related emissions in the cement industry can also be reduced, in part, through the use of clinker substitutes, this is not possible in the lime industry. It was precisely this aspect that led to the collaboration between Kalkwerke Oetelshofen in Wuppertal/Germany, which celebrate its 125th anniversary in 2025, the start-up company Black Capture, Calcis and Bergmann Kalk. In an interview with ZKG, Till H. Iseke, Managing Director of Kalkwerke H. Oetelshofen GmbH & Co. KG, and Martin Pietrowski, Managing Director of Black Capture, take stock of how the pilot plant for CO2 capture has affected processes at the lime plant after six months and venture a look ahead at further joint goals and the future of the lime industry.

Iseke: The first small quarry was already marked on the map at the place where we are sitting today – along with the agricultural business in the year 1750 from which this company originated, of course. There has been a relatively large amount of limestone mining here around, and it is still taking place. The largest limestone quarry in Europe, Flandersbach, is only five kilometers away.

What is interesting is that over the many decades of industrialization – the Ruhr region, the iron and steel industry – lime has naturally also grown in importance. At that time, the individual steelworks – Krupp, Mannesmann, Thyssen – had their own quarries and lime works. Gradually, these smaller plants merged and merged, and ultimately became Rheinkalk, which in turn became Lhoist. We are the only medium-sized family business in our region that has remained independent since 1900. That‘s why our logo says “Independence obliges”.

We have 100 employees, including the management. In the quarry sector in particular, there are another 15–20 people working for subcontractors or external companies who cover specific areas of responsibility.

As for the figures: we move a total of around 2 million tons of material here every year, which of course includes overburden. And since we are below the groundwater level, we pump out around 8 million cubic meters of groundwater per year. This flows directly into the Düssel river here at the front – which flows “through the garden” to Düsseldorf, so to speak. Most of the water is returned there. Most of the pumped groundwater therefore flows back into the Düssel.For me, the most interesting aspect of the lime industry is the lime cycle: Calcium carbonate (CaCO₃) Calcination: CO₂ escapes, calcium oxide (CaO) remains Slaking with water: Calcium hydroxide (Ca(OH)₂) and then – not in all, but in many products – recarbonation: The CO₂ released in the process is later reabsorbed.

What‘s exciting about lime is that around 33% of its applications result in CO₂ being reabsorbed, as you can see for example for the plaster on the walls. Besides using more sustainable fuels in our kilns, e.g. biomass, we still have to come up with something else for the rest of the CO2.

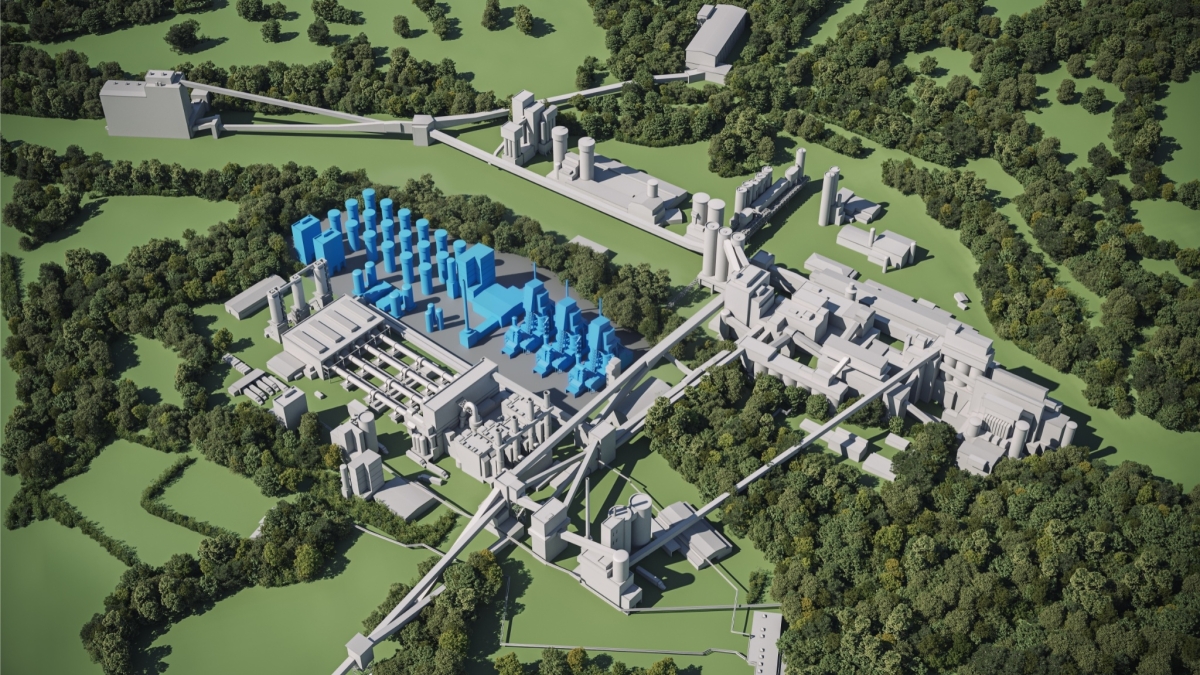

Our core units are two kilns from the QualiCal company in which we produce the lime. We built the first one in 2007 – a worldwide prototype, the first kiln from QualiCal (an Italian engineering firm). It was a huge risk, investing half of our annual turnover at the time. Fortunately, it worked out well. We built the second one in 2013. This type of kiln can now be found all over the world.

We have a capacity of 400 tons per day per kiln, or 800 tons per day in total. So back then, we laid the foundation for having the most efficient technology available in this field.

Iseke: We divide our products into unburnt (minerals) and burnt – and then, of course, into different grain sizes: from mineral mixtures for road construction, high-grade chippings, and grit to limestone powder, which is increasingly being used as a clinker substitute or in flue gas cleaning.

As far as the unburnt portfolio is concerned, magnesium-rich batches from the quarry go into the mineral mixture sector. Everything that is “blue” – as we call calcium carbonate-rich zones – goes into chippings and limestone powder; as lump lime, it goes into the kiln, selectively for the iron and steel industry, finely ground as white fine lime for the construction industry/sand-lime brick industry, but also for a wide variety of other industries.

Currently we increase our production for hydrated Lime. In our product portfolio we have already certified products like Milk of Lime for drinking water and wastewater applications, powdered Hydrate lime for environmental and construction use.

ZKG: Where is the lime industry on the path to CO2-free production processes?

Iseke: Everything is in flux at the moment. If our customers manage to switch to a virtually CO₂-free production process in terms of process technology – Scope 1 goes down significantly, Scope 2/3 remain – then the lime required for this will account for the largest share of their footprint. That‘s not ideal, of course, but that‘s the logic. Roughly 1 ton of CO₂ is produced per ton of burnt lime. Roughly one third of this comes from the fuel, two-thirds from the process (calcination). Biomass will tend to be the issue here; even with completely renewable fuel, the unavoidable process-related emissions remain, similar to cement or waste incineration. With cement, clinker substitutes can be used to reduce emissions somewhat; this is not possible with us, which is why we need carbon capture: in existing kilns – here we use the Black Capture approach – and, of course, in the chain that follows (liquefaction, transport, compression). Or kiln technologies in which the CO₂ is produced in a highly concentrated form – easier to liquefy and separate.

Regarding recarbonation: the The European Lime Association EuLA estimates ~33% CO₂ reintegration across all applications. So, roughly one-third of the ton of CO₂ per ton of lime is later re-bound. If modern kilns switch completely to biomass (and this is recognized as 100% CO₂-neutral) and this ~33% recarbonation is also recognized, then ~0.33 t CO₂ per ton of lime remains, which we have to capture and render harmless. In the long term – with 100% capture and biomass – negative emissions would even be possible (double leverage from recarbonation + bio-CCS).

Iseke: We find Black Capture‘s technological approach exciting. One thing is clear: in terms of regulation, economics, politics, and infrastructure, there is still a lot to be done. We are at the very beginning, but we are taking decisive steps. In Norway (e.g., Brevik), you can see the dimensions – a chemical factory next to the cement plant. Amin washing is usually out of the question for the lime industry because our kilns are so efficient that we lack the waste heat. And Amin is the only thing that can currently be purchased “off the shelf” on a large scale.

In general the investment costs are high for carbon capture: several million per kiln – regardless of whether amin scrubbing, membranes, etc. are used. More interesting are the operating costs, the ongoing energy requirement per ton of CO₂ captured. With amin scrubbing, this is high. Since we have no waste heat, the question does not even arise. So we looked for the most cost-effective process – in our opinion, that was a mechanical one. No major heating processes, no high pressures. With membranes, separation is selective; the electrical input is relatively low.

For us, the operating costs are decisive. The question is: Which type of membrane should be used? We like zeolite (ceramic) membranes – they could be more stable than polymer membranes, which degrade in aggressive exhaust gases. Their performance is also better.

Pietrowski: Regarding the operating principle of our CO2 capture plant: We have a membrane, similar to a molecular sieve. We apply pressure to the exhaust gas (compressor), it flows through the membrane tubes; the pressure causes CO₂ to pass through the membrane. On the other side, we have negative pressure (vacuum pump) to optimize the pressure difference and energy efficiency. This expels the remaining exhaust gas and the CO2 gas is ready for utilization or compression.

The technology is energetically viable from ~10% CO₂ in the flue gas. In the lime plant, we have ≥ 20%, where the membranes work very well. The more CO₂, the better. The separation problem is usually N₂ vs. CO₂. N₂ tends to be retained, while CO₂ passes through the membrane. In the single-stage plant, we have ~20% CO₂ in the feed – tending to be more – and already achieve > 80% CO₂ in the permeate. Classically, multiple stages are used to increase concentration and separation rate – we are planning this for the future.

Important questions here are the service life of the membranes, the energy consumption, and the scaling (high capacity, increase in stages). We have tested different modes: a lot of exhaust gas (more throughput) vs. less exhaust gas (higher selectivity/concentration in the permeate). You have to be sure about the scaling. Depending on the requirements, Black Capture offers system designs with its container modules. Multiple modules match then the specific capacity need.

The advantages of the membrane process: it is modular, can be switched on/off quickly, and requires little maintenance, which is all in all a elegant solution. Compressors and vacuum pumps are serviced regularly, but the membranes themselves hardly ever. We expect the ceramic membranes to have a service life of at least 10 years – significantly longer than polymer membranes.

Pietrowski: Black Capture has officially existed since the beginning of 2024, but the groundwork for this has been underway since 2021/2022. The basic idea: Industry has CO₂ emissions that can only be reduced through capture – why isn‘t anyone using it? The answer: too expensive, too much maintenance, trained personnel required – many plants don‘t want that; they focus on their core business. That‘s how we came to membrane technology and ceramic membranes, and built the team accordingly. The next step was Circular Valley, a start-up program with a strong industrial network.

I met Mr. Moritz Iseke during a factory tour here in Oetelshofen. He found our idea interesting, and this led to more in-depth discussions. After some time, we decided together: “We will build a CO₂ capture plant with the aim of gaining maximum knowledge about the process and the effectiveness” Oetelshofen suggested bringing in additional partners: Bergmann Kalk and Calcis – as a lime consortium together with Black Capture. The plant has been in operation since February 2025; it took about six months to set up.

About me: I come more from a software background (devices/machines) and have gradually moved into hardware and products/solutions, with sales experience. Our Technical Director Andreas Elli (a process engineer) was in charge of planning the plant. We built the plant completely on our own so that we gain the maximum knowledge gain from this project. In the future, we’re only focussing on membrane production as well as our module container plant designs. Since 2021, I have been responsible for sales in the industry and have built up further expertise in the field of CO₂ capture.

Pietrowski: Our interim conclusion after six months:

Low maintenance: Our membranes do net need to be replaced any time soon & we do no need to regenerate the membranes

Degradation: our target was a service life of 10 years; with our insights we are more likely to achieve at least 10 years

Energy efficiency: target 200-350 kWh/t CO₂ (when extrapolated to a larger plant). We adjusted the projections based on the operating parameters and got a clearer picture of the efficiency we could achieve

It was important for us to show that it works technically—not in the lab, but in the running plant at the lime works. Lime works are not the least dusty places; it‘s rough — and yet it works 24/7. That‘s a great success.

Pietrowski: In applications with ~10% CO₂ or more, wherever flue gases are produced. Theoretically, it could also be used in direct air capture. We used ambient air out of curiosity and already achieved 3–4% CO₂ concentration in the first stage; with several stages, DAC would be possible. Black Capture can also be used in the following areas:

Heavy industry cement and lime production, steel and iron industry, chemical and petrochemical manufacturing

Energy thermal waste utilization, natural gas and biogas power plants, natural gas processing, bio-cogeneration plants

Additional sectors glass manufacturing, paper manufacturing, sewage treatment plants, ships

The combination of technologies is also exciting: first increase the CO₂ content and then use the membrane – or vice versa (membrane as “pre-feeding” for other processes, with less pre-filter technology). Modularity allows capacities to be adjusted as required.

Iseke: As next steps, we are planning a targeted gas analysis – what passes through the membrane and what does not – and discussions are also underway about scaling or expanding the separation plant. However, we will only take stock after ~ one year of operation.

Pietrowski: In the future, intermediate tanks for liquid CO₂ will probably have to be installed at the site, and then it will be transported away. Depending on the location, this is a separate project, because some sites first utilize the CO₂, while others compress it and transport the CO2 away.

Carbon utilization is also an interesting area in principle, but it is challenging, especially in terms of energy requirements. Industry emits a great deal of CO2, which naturally raises the question of how much of this CO2 can actually be utilized. Based on current estimates, a very optimistic 12% of the emissions produced can be utilized, while the rest still has to be disposed of by other means.

Iseke: The overall balance is crucial. Sector targets are political; the climate doesn‘t care where the reduction happens. With 100% capture plus biomass and recognized ~33% recarbonation, even negative emissions are possible. The important thing is to make a start. The rest – infrastructure, regulation, logistics – will follow.