Cement and building product industries benefit from new market approach with the Portland Company’s rotating PANTHERA-PACKER PVT®

The Portland Company, offering the world’s first Assemble to Order (ATO) packing equipment product line in partnership with Haver & Boecker, offers the PANTHERA-PACKER PVT packer*. This predefined rotary packing machine provides a standardized approach to filling industrial bulk materials in valve bags that range from 25 kg to 50 kg in size. Designed with robust and proven slide gate dosing technology, the PANTHERA-PACKER PVT is a high-quality, yet quick and very cost-effective bag filling solution, designed with state-of-the-art components for the cement and building materials industries. The Portland Company’s ATO approach is ideal for plants that require quick installation without additional customizations.

“The Portland Company was developed to provide customers with high-quality and reliable packing solutions in a more price-and-speed-sensitive, preconfigured machine,” said Francesco Ferrandico, The Portland Company’s Managing Partner. “We are combining German engineering with Italian design to form a packing line that offers customers quality they can rely on while cutting down on lead times.”

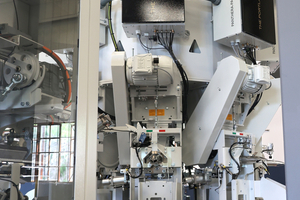

The PANTHERA-PACKER PVT is available in configurations of 8, 12 or 16 spouts in a simplified design that is easy to operate and maintain. The 8-spout model has the capacity to fill up to 3000 bags per hour depending on the bag size and material to be bagged. Dedusting at the spout expels contaminants and a well-proven dosing sliding gate ensures accurate dosing of material and a clean filling process. A specially designed three-position cylinder provides the precision at the heart of the filling system. The PVT’s weighing system is the MEC® 4.0, provided by Haver & Boecker. It maintains accurate package fill amounts to optimize profitability. The PANTHERA-PACKER PVT is a preconfigured machine for quick and economical installation without sacrificing quality. The equipment is manufactured in Oelde/Germany and contains original Haver & Boecker components for all primary functions. The PVT can be easily upgraded for a simple pathway to growth.

The Portland Company places a high degree of focus and importance on service and attention to the customers’ full operational needs. The signature PROcheck approach centers on keeping customers’ operations running at peak performance. PROcheck can identify systems that will help automate the packing process, oversee equipment currently in use and offer solutions to configure the line for improved efficiency and reduced labor. In this way, the PANTHERA-PACKER PVT fits within a larger packing triangle of products, bags and machine to give the customer a comprehensive experience with the packing process and ensure a steady, reliable and efficient material flow. The Portland Company’s testing center in Oelde, Germany, complements this flow triangle by testing bags to ensure the right machine settings for each bag or help to recommend the right bag.