Cement’s green challenge isn’t just emissions - it’s process variability

Cement production has always been a complex balancing act of meeting process targets, but the level of variability in today’s plants is unprecedented. Alternative fuels vary in calorific value and moisture content from one delivery to the next. Supplementary cementitious materials (SCMs) shift raw mix chemistry in ways that are difficult to predict. All of this must still be managed while keeping clinker quality consistent and equipment running smoothly. The real Green Challenge isn’t simply reducing emissions - it’s mastering the growing operational complexity without losing efficiency or profitability. It’s within this environment that artificial intelligence (AI) is starting to prove its value. Instead of relying on static control models, AI learns directly from plant data, recognising patterns and anticipating how changes in one part of the system will affect another. In practice, this means kilns that stay stable even at higher thermal substitution rates, grinding circuits that consume less energy while maintaining quality, and process conditions that are consistent enough to drive down the costs of future carbon capture. For producers already working under these pressures, AI is a practical tool for managing variability driving greater efficiency, significant cost savings, and progress toward decarbonisation.

Mastering complexity – Why a new control layer is needed

Distributed Control Systems (DCS) and Advanced Process Control (APC) have long been the backbone of plant control, bringing all key process controls into one coherent system and stabilising processes around fixed setpoints. But as variability grows — from higher thermal substitution rates (TSR), fluctuating feedstock, and tighter emissions limits — APC systems struggle to keep up. What’s more, re-tuning APC systems is time-consuming and specialised. While service contracts with APC providers are available, internal expertise is preferred, as when confidence falls, operators often switch back to manual control. However, with frequent turnover in process engineers, the in-house experts have often moved on when tuning is required.

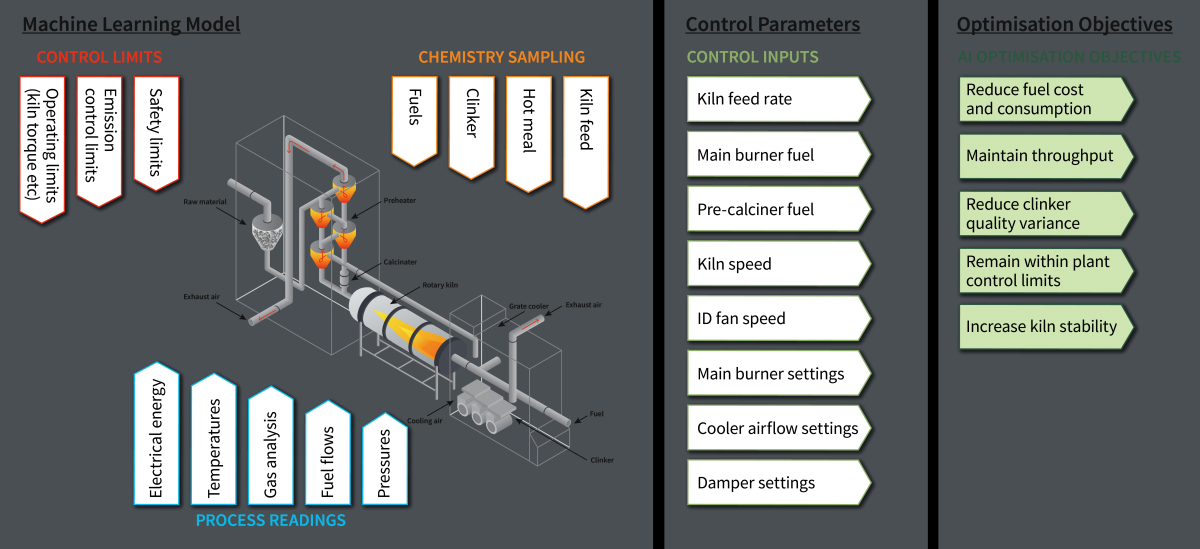

How is AI control different? Well, AI brings adaptability through more sophisticated modelling. AI handles more data points and thinks through all the potential scenarios iteratively, much like how a process engineer would, rather than just a simple extrapolation, resulting in smoother control. Unlike APCs, AI models also learn directly from plant data. This means that the models are continuously retuned, ensuring that set point target recommendations are correct even as plant conditions change.

Crucially, AI is not a replacement for operator oversight. It complements it. AI acts as a co-pilot for process engineers, providing intelligent decision support in a system that has a holistic view of the plant. What’s more, we’ve seen that AI has improved operator trust of control systems like at Cimsa’s Eskeshir plant. Ali Camgoz, Director of Operations, explained that before Carbon Re it was challenge to keep the plant’s expert system on. Now with Carbon Re, the use of their expert system is up, the limits are wider and operators trust the system.

Burning smarter: combining alternative fuels and AI

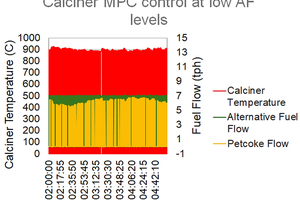

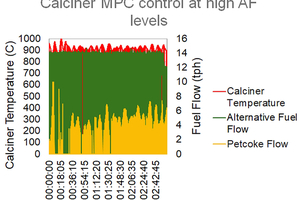

Let’s look at a common situation plants face today. Many plants, particularly across Europe, are using alternative fuels. But the variation in alternative fuels brings significant process variability, causing fluctuations in temperature, air-fuel ratio, and burning zone conditions. This makes kiln stability and operational efficiency hard to reach, particularly without an adaptable system.

We’ve seen this time and time again in our customers‘ data. The static logic in conventional control systems can’t keep up with the rapid shifts in fuel quality or calorific value. The result is overcorrection, delayed responses, and more manual interventions.

AI unlocks what traditional control systems can’t: the ability to capture the complex, non-linear relationships between fuel properties, temperature distribution, and clinker quality. By adjusting fuel and air inputs dynamically, it keeps the kiln both thermally and chemically stable.

Trained on historical plant data, AI doesn’t just react; it anticipates. It can predict how different fuel mixes will affect combustion and set process targets in advance, before fuels hit the system. Integrated in closed-loop control, this creates a more stable, truly hands-free operation.

The result is greater stability and less time spent firefighting. By managing combustion in real time, AI reduces the burden of fluctuating fuels and rigid legacy systems, giving operators the time to focus on higher-value operational projects.

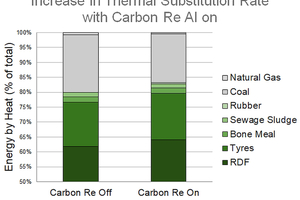

At the Heidelberg Materials Mokra plant in Czechia, Carbon Re increased the thermal substitution rate (TSR) and reduced fuel costs by more than 3%. Crucially, this was achieved while maintaining specific heat consumption, respecting stack emission limits and improving clinker quality - even with the high variability of refuse-derived fuel. Rather than pushing the kiln harder or forcing more alternative fuels at the cost of efficiency, Carbon Re’s AI model and controller enabled the plant to burn smarter. Beyond the production KPIs, the plant team gained confidence in AI-powered control.

“Carbon Re is a really powerful tool and I really like using it. It allows us to run closer to the bounds of our ID fan’s limit – but on the safe side.” Jiří Matykan, Mokra Pyroprocess Engineer

AI and the Green Opportunity ahead

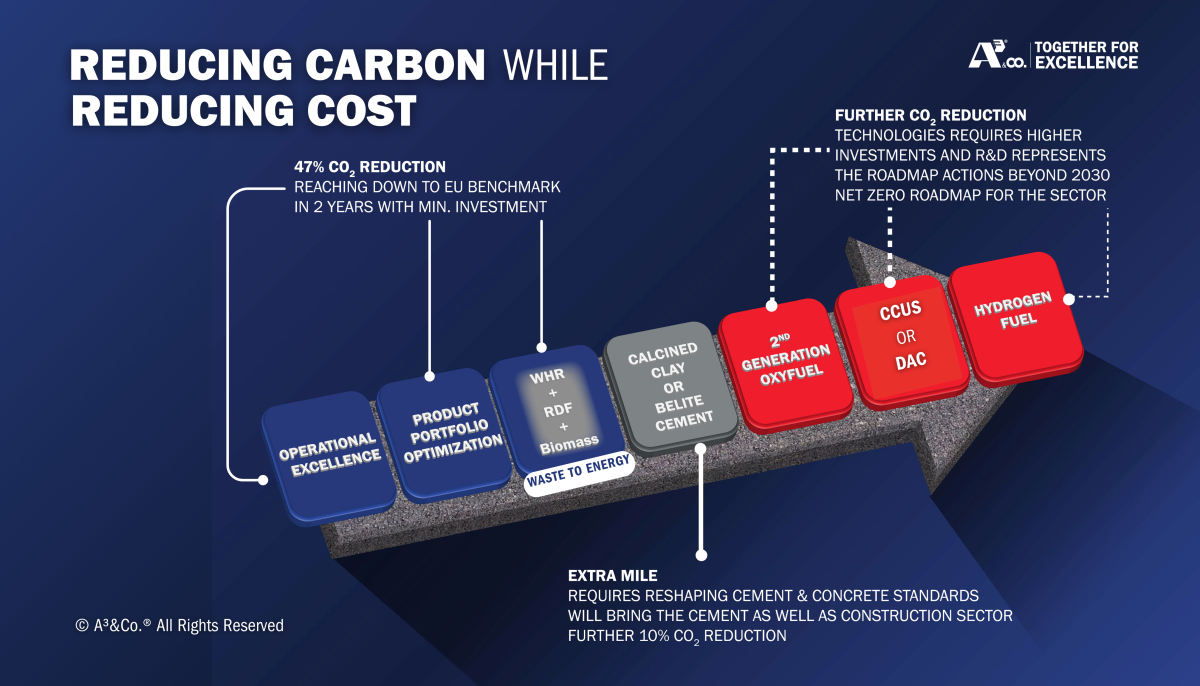

While not yet commonplace, carbon capture systems will soon be. Much has been made of the costs associated with carbon capture and storage (CCS) - capture alone can increase cement production costs by over 50%, depending on the technology used and the regulatory environment. But there has been less of a focus on the process stability needs to ensure economic viability. Of course this makes sense, with the first industrial scale systems only just starting to come online. But

Less has been said about the need for a highly stable process. This is where AI makes a difference. By monitoring, interpreting, and optimising in real time, AI can help by stabilising upstream processes:

Tighter oxygen control reduces solvent degradation

Stable flue gas composition allows smaller, more cost-effective capture units

Predictive optimisation balances kiln efficiency with CCS operating needs

Our research shows AI can cut CCS costs by at least $ 10/t of CO₂ — through lower energy use, smaller capture units, and longer solvent lifetimes. In short: AI today makes CCS tomorrow technically and economically viable.

Cement’s Green Challenge is clear: decarbonise while staying competitive. Producers need tools that deliver immediate performance gains and prepare plants for future technologies like CCS.

AI process control is already proving its value enabling plants like Mokra and Eskeshir to increase thermal substitution rate and cut while improving clinker quality and kiln stability. These are real, measurable gains that reduce both emissions and costs.

At the same time, AI builds the stable foundation required for the next phase of decarbonisation. By mastering variability, it ensures CCS and other innovations succeed without undermining efficiency. AI is not a distant promise — it’s here, it works, and it will be essential for meeting cement’s biggest challenge head-on.