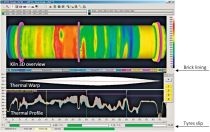

Complete rotary kiln equipped with full automatic IR-temperature control based on water spray cooling

Heidelberg Materials is pushing boundaries with the modernisation of its plant in Slite on the Swedish island of Gotland. It is set to become a plant that can produce climate positive cement, using ambitious carbon capture and emission reduction technologies.

The German company Kima Process Control GmbH will supply the most energy-efficient and environmentally friendly kiln shell cooling system for the entire kiln length of 55 m: a KilnCooler ‘stationary’.

The concerns about using water to cool the furnace shell have been dispelled in recent years. Long-term studies by users of Kima Process’ patented technology show that there are neither changes in the molecular structure of the iron (hardening) nor micro-cracks in the outermost layer of the furnace shell due to the evaporation of water. The manifold advantages of the technology have moved Slite to use 88 water jets instead of various powerful air blowers, which cool the furnace with centimetre precision only where it is really necessary to protect the furnace steel and refractory material.

The switch from electrically driven fans, which consume up to 2 million kWh of electricity per year, to industrial water not only results in a reduction of up to 1700 t of CO2, but noise emissions are also drastically reduced, according to the VDZ (Association of German Cement Works). For the nearby residents of the plant in Slite, this will mean a massive improvement and Heidelberg Materials will also save immense operating costs, as water in the quantity used only costs 2% compared to electricity.

In addition, pinpoint cooling also brings significant advantages in process engineering. By means of IR pyrometers, the furnace shell is precisely measured to within 10 cm2 and a current target temperature is specified every half meter. This temperature, which depends on the degree of refractory wear, is now secured around the entire kiln circumference by means of a water spray.

A very uniform buildup in the kiln protects the refractory material and ensures much quieter kiln operation. Heat energy supplied by the main burner is not lost through unnecessary cooling of the furnace shell. This also means less fuel use. Deformations of the kiln shell can be reduced, if not prevented, at an early stage.

The investment in the intelligent kiln shell temperature control by Kima Process Control’s KilnCooler ‘stationary’, will bring the cement plant in Slite an economic benefit in the shortest possible time, but for the cement industry this project represents a new milestone in terms of BAT – Best Available Technology – in the operation of rotary kilns.