Decarbonization technologies and application in China’s cement industry

1 Introduction

As one of the most important basic materials in modern construction industry, cement faces the dual challenges of high energy consumption and intensive carbon emissions during its production process [1-2]. According to statistics, the average manufacture of 1 ton of cement currently produces about 0.6 ton of CO₂, making the cement industry the third largest source of CO₂ emissions after electricity and steel [3-5].

With the deterioration of global climate change and the global commitment of carbon neutrality goals, decarbonization in the cement industry has become a research hotspot in academia and industry community. This paper systematically sorts out the cutting-edge achievements of decarbonization technologies in the China’s cement industry in recent years, elaborates on the characteristics, carbon reduction effects and application prospects of various technical routes, and provides technical underpinning and applied guidance for the green transformation of the cement industry. The full text first analyzes the current situation of carbon emissions in traditional cement production, then analyzes the principles and application of major decarbonization technologies, including the outcome of these case studies in terms of energy efficiency, decarbonization and circularity, and finally concludes by summarizing the current challenges and outlining the future development directions.

2 Current Status of Carbon Emissions from Traditional Cement Production

Cement manufacturing is an extremely complex process, and its carbon emissions vary depending on calcination processes, technology levels of equipment and cement types. Based on previous statistics on carbon emission distribution, see Table 1[6], clinker calcination section is the main source of CO₂ emissions, accounting for over 95% of total emissions, of which CO₂ produced by limestone calcination and decomposition accounts for 50-60% of total emissions, and CO₂ produced by fuel combustion accounts for 30-40%.

According to the U.S. Geological Survey (USGS), global cement production was approximately 4 billion t in 2024, with CO₂ emissions of 2.4 billion t, accounting for 6-8% of global total emissions [7-8]. As the world’s largest cement producer, China’s cement production in 2024 was 1.825 billion t [9], resulting in an estimated 1.1 billion t of CO₂ emissions, accounting for 12-14% of the country’s total emissions. The data highlights the key role played by cement industry in carbon reduction process.

To promote sustainable industrial development and achieve the goals of the Paris Agreement on Climate Change, a clear global decarbonization goal and roadmap has emerged, with the Global Cement and Concrete Association (GCCA) having released “Concrete Future-The GCCA 2050 Cement and Concrete Industry Roadmap for Net Zero Concrete” and “Net Zero Accelerator” plan [10]. China has proposed “3060” dual-carbon goals based on national conditions, and China Building Materials Federation has simultaneously promoted the construction of “Six-Zero” demonstration factories in the building materials industry. Key pathways to achieve these goals include improving energy efficiency, alternative raw materials and fuels, new low-carbon clinker cements, and CCUS and so on.

3 Research Progress on Decarbonization Technologies

3.1 Energy Efficiency Improvement

Driven by national policies, particularly the promulgation of GB 16780 – 2021 “The Norm of Energy Consumption per Unit Product of Cement”, reducing carbon emissions in the cement production process has become a crucial issue that needs to be urgently addressed. Energy efficiency improvement technologies focus on optimizing energy efficiency throughout the entire process. Through multi-dimensional collaboration involving system energy consumption reduction, power consumption control, efficient waste heat recovery, and digital & intelligent management and control, significant effects of carbon emission cut can be achieved.

In terms of clinker calcination, the integrated application of multiple technologies has enabled major breakthroughs in energy efficiency improvement. Advanced technologies and equipment such as new thermal insulation materials (nanoplates, aerogels), gradient combustion self-denitrification calciners, fourth-generation coolers, and high-efficiency low-resistance preheater systems have been adopted. These measures can drive down heat consumption to 620-640 kcal/kg.cl, and significantly improve clinker cooling efficiency and heat recovery rate [11-13]. In terms of grinding, the most advanced roller press final grinding technology and equipment are used. Under conditions of moderate grindability, power consumption of raw meal grinding system is reduced to 12 kWh/t. The power consumption of cement final grinding system equipped with multi-rotor separators is as low as 21 kWh/t, and that of fuel vertical roller mill grinding system is as low as 25 kWh/t [14-15]. In terms of environmental protection, the use of high-efficiency bag filters can control dust emission concentration below 5 mg/Nm³. Wet desulfurization technology can meet the ultra-low emission requirements of SO₂ in the scenarios of sulfur-containing raw materials. The adoption of flexible SCR nitrogen oxide treatment schemes, such as high-temperature high-dust, medium-temperature medium-dust, and high-temperature low-dust schemes, can stably meet the strict requirements of NOx emission < 50 mg/Nm³ [16-17]. In addition, waste heat recovery and intelligent control technologies have further improved the energy efficiency system. With the widespread application of waste heat power generation facilities, the power generation of clinker per ton reaches 28-32 kWh, which can meet the electricity demand of calcination system and realize the isolated operation of calcination system. The integrated application of intelligent control systems, digital carbon emission control systems and BIM technology can reduce heat consumption by more than 3%, achieve a grinding intelligent system operation rate of over 98%, and reduce energy consumption by more than 5% [17-18].

At present, these technologies have been applied on a large scale in new and upgrading projects in China. Through the collaboration of production process optimization, environmental protection upgrading, waste heat recovery and utilization, and intelligent management and control, a full-process energy efficiency optimization system has been built. Specific application cases can refer to Figure 1-2 and Table 2-4 [19].

At present, the existing technical indicators of clinker heat consumption and comprehensive grinding power consumption in China’s cement industry have reached the international advanced or even leading level. Unless disruptive technologies such as fluidized bed, electrification, and solar energy emerge, the potential for further emission reduction through this technical pathway will be limited.

3.2 Clinker Substitution

Clinker substitution technology involves replacing clinker with slag, fly ash, and other pozzolanic admixtures, while ensuring no adverse impact on cement quality and performance, represents a crucial pathway for low-carbon development in the cement industry. China’s cement industry leads globally in the application and development of this technical route, with the current average clinker factor at 0.66.

Calcined clay technology is currently one of the international hotspots. Without compromising performance, calcined clay combined with limestone can replace up to 30-50% of clinker and even more depending on the activity and strength grade of the resultant cement. The new ternary system cement LC3 (Limestone-Calcined Clay-Cement) is composed of limestone, calcined clay, gypsum, and clinker. In this cement, limestone reacts with calcined clay to form calcium carboalumination hydrates, which promotes cement hydration. It maintains performance comparable to ordinary Portland cement even at a clinker substitution rate as high as 50% [20].

Current calcined clay processes include rotary kiln, fluidized bed, and suspension calcination technologies. Among these, the suspension calcination process is considered the optimal technical route available today due to its significant reduction in production energy consumption. Sinoma International independently developed and built the 600 t/d kaolin suspension calcination production line in Zhenjiang (Figure 3), achieving a breakthrough in large-scale suspension calcination production of kaolin tailings in China. The calcination heat consumption is approximately 450 kcal/kg, more than 40% lower than that of rotary kiln systems. Therefore, using calcined clay to replace 30%-50% of clinker in cement production achieves extremely significant carbon emission reduction effects, and the benefits generated from carbon emission reduction can offset the production cost of calcined clay.

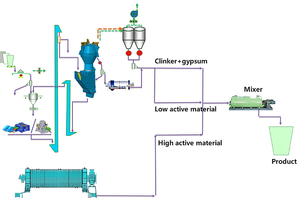

Enhancing clinker quality and optimizing grinding technology are also the key approaches to achieving low-carbon targets. Improving clinker quality is undoubtedly the primary strategy for enabling increased addition of supplementary cementitious materials (SCMs) without compromising the key performance of cement. The core technical pathways for enhancing clinker quality focus on four aspects: optimization of raw material proportions, advancement of calcination processes, application of mineralizers, and implementation of intelligent control systems. Meanwhile, separate grinding technology, developed based on hydration characteristics of cement, offers an effective solution for reducing clinker content. By implementing differentiated grinding control for various materials, vertical roller mill or roller press are employed for separate grinding of materials such as clinker, gypsum, and limestone. An exemplified process flow is illustrated in Figure 4. Practical applications demonstrate that this technology can further reduce proportion of clinker by 10%~15%, thus effectively lowering carbon emission intensity [21-22].

3.3 Low-Carbon Cement

The four primary mineral phases in ordinary Portland cement clinker are associated with wwdifferent levels of CO₂ emissions during their formation, with Alite (C3S) being the largest contributor (Table 5). In accordance with the national standard for Portland cement clinker and common production practices, it is also the most predominant phase in the clinker [23]. For this reason, a variety of new low-carbon cement types have emerged internationally, which achieve emission mitigation by optimizing and/or introducing new mineral composition and reducing calcination temperature.

Representative technologies and products originating from China include calcium sulfoaluminate cement (CSA), high belite cement (HBC), and belite-calcium sulfoaluminate cement (BCSA). Their designed chemical and mineral compositions are summarized in Table 6. Specifically, each cement type possesses distinct technical characteristics, as outlined in Table 7 [23].

By innovating in mineral composition, lowering calcination temperatures, and enabling higher clinker substitution rates, these new low-carbon clinker cement systems significantly reduce carbon emissions during production. They thus provide multiple technical pathways for the low-carbon transition of the cement industry. Although their current production volume remains limited, their potential for energy savings and emission reduction is substantial and is expected to grow steadily as the market for these technologies expands.

3.4 CCUS

Carbon Capture, Utilization, and Storage (CCUS) technology is a critical technological solution that will be indispensable for decarbonization in the future. The main application directions currently are post-combustion carbon capture and in-combustion carbon capture (specifically oxy-fuel combustion technology) [24-26].

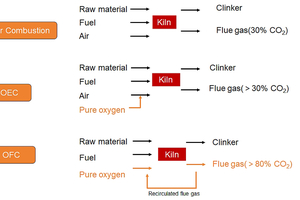

Specifically, although carbon capture technology of post-combustion chemical absorption has a wide range of applications, its total energy consumption is relatively high; while oxy-fuel combustion technology has attracted extensive attention due to high feasibility and low-cost advantages in existing cement plants [27-30]. The oxy-fuel combustion carbon emission reduction technologies in the cement industry are mainly divided into oxygen-enriched combustion (OEC) technology and oxy-fuel combustion (OFC) technology, as shown in Figure 5: OEC technology uses oxygen-enriched air with an oxygen content higher than ordinary air (21%) as combustion-supporting agent to enhance fuel combustion efficiency and heat utilization rate; OFC technology mixes high-concentration O₂ prepared by air separation devices with 60%~70% recycled flue gas to form an O₂/CO₂ atmosphere, replacing air as the oxidant. The high-volume fraction CO₂ generated by combustion can be directly utilized or stored after compression and purification [31-36].

In terms of technical research and application, European Cement Research Academy (ECRA) has established a parallel direction of partial oxy-fuel combustion (using pure oxygen combustion in calciner) and full oxy-fuel combustion (using pure oxygen combustion in the whole process, including calciner and rotary kiln) [37-42]; The CEMCAP project funded by the EU “Horizon 2020” has developed advanced carbon capture technology to provide a basis for full-scale transformation of cement production processes [42-45]. While the AC2 project has carried out industrial retrofitting demonstrations in companies such as HeidelbergCement and Lafarge Holcim, forming an upgrading guide for existing cement plants. In response to the national “dual-carbon” goals, in 2018, Conch Cement built a demonstration line for carbon capture and purification from cement kiln flue gas in WH cement plant, which pioneered the recycling and utilization of CO₂ in the global cement industry and set a leading pilot benchmark for carbon emission reduction in the industry. In 2022, Sinoma International built the first full oxy-fuel combustion pilot test platform, and its output was applied in the 200000 t/a demonstration project of CUCC (QZ) [46]. Currently, leading enterprises such as China National Building Materials (CNBM) and Conch Cement have built or plan to carry out relevant demonstration projects. The CCUS projects under construction or in operation in China’s cement sector and the main applied technologies are shown in Table 8 [47].

However, CCUS faces significant challenges, including high upfront investment, persistently high carbon capture and utilization costs, and the unresolved issue of how to utilize or store the captured CO₂.

3.5 Alternative raw materials and fuels

Alternative raw material and fuel technologies in cement production include the substitution of calcium-based raw materials, the use of alternative fuels, and co-processing waste in rotary kilns. A representative case of non-carbonate calcium material utilization is the application of carbide slag. Currently, the alternative fuel substitution rate in China’s cement industry remains below 10%, indicating substantial potential for future emission reduction.

3.5.1 Alternative raw materials

In cement production, the high-temperature decomposition of calcareous raw materials is a significant source of carbon emissions. Alternative raw materials can effectively reduce emissions, providing a feasible pathway for low-carbon transformation in cement industry.

Cement production uses limestone as main calcareous raw material, with approximately 1.3 tons of raw materials consumed by producing one ton of clinker. A large amount of CO₂ is generated during its decomposition. However, in practice, as long as raw material does not decompose or its decomposition products do not contain CO₂ during application and can provide CaO, it can be used to produce qualified clinker. Information on common alternative raw materials is shown in Table 9.

China has long engaged in innovative practices regarding alternative raw materials. Specifically, the application of carbide slag as a substitute is relatively mature. For example, Sinoma International has designed the 300 000 t/a carbide slag cement production line in Yibin. These projects have achieved reliable utilization of carbide slag through technical transformation. Silica-calcium slags such as fly ash and coal gangue, where calcium elements do not exist in the form of CaCO₃, can theoretically cut carbon emissions from fuel combustion required for CaO decomposition and from carbonate decomposition. They also offer the advantages of reducing carbon emissions and improving land utilization.

Steel slag can improve the burnability of raw meals and reduce fuel combustion emissions. However, variations in composition due to different steelmaking processes require adjustments to raw meal formulations. Otherwise, it may cause instability in cement quality, limiting its reuse [48]. Regarding quartz sludge, CUCC has replaced sandstone with quartz sludge in its 4600 t/d production line through technical transformation, which improved the grindability and compositional stability of raw meal and significantly enhanced production efficiency.

Papermaking sludge can not only be used as raw material but also, due to relatively high calorific value, can replace part of fuel. Theoretically, for every 1% wet papermaking sludge incorporated, the physical coal consumption per ton of clinker can be reduced by 1.91 kg. In addition, the industry has actively promoted the use of bulk solid wastes such as phosphogypsum for raw material substitution in recent years. For instance, the WF phosphogypsum resource decomposition project designed by Sinoma International has achieved 100% replacement of limestone.

In conclusion, the use of carbide slag, silica-calcium slag, steel slag, and other materials to replace traditional calcareous raw materials can not only meet the demand for CaO in cement production but also reduce carbon emissions at the source while realizing the resource utilization of industrial solid wastes.

3.5.1 Alternative Fuels

As an important means for cement industry to reduce reliance on fossil fuels and lower carbon emissions as well as harmful gas emissions, fuel substitution technology, which replaces traditional fossil fuels with renewable energy sources such as waste or biomass, has been adopted worldwide. Meanwhile, the exploration of new alternative fuels such as hydrogen energy has opened up additional pathways for low-carbon transformation of cement industry.

Specifically, fuel substitution technology targets waste or biomass with certain calorific value as substitutes. Internationally, Thermal Substitution Rate (TSR) is commonly used to measure the substitution ratio, i.e., the proportion of heat provided by alternative fuels in the total heat of kiln during calcination process. In terms of application status, the average fuel substitution rate in EU cement industry has approached 40%. However, the utilization rate of alternative fuels in China is less than 10%, mainly limited by the small coverage of waste classification areas and the lack of unified grading standards for waste components [49]. In specific applications, municipal solid waste has a wide range of sources, and processing it into Refuse-Derived Fuel (RDF) can improve the stability of fuel quality. Currently, China mainly adopts two feeding methods: single-point direct injection or pre-combustion before entering decomposing furnace (the characteristics of each method are shown in Table 10). In 2024, HX cement has achieved a stable fuel substitution rate of over 60%, with comprehensive energy consumption of clinker below 50 kg of standard coal per ton. The WAXF project, as shown in Figure 6, constructed by Sinoma International, establishes a new comprehensive circular economy model anchored in cement kiln co-processing. This system integrates the treatment of diverse waste streams—including industrial solid waste, municipal solid waste, hazardous waste, and construction waste—enabling the company’s strategic evolution from a traditional building materials manufacturer to an urban environmental service provider and green materials supplier. This initiative presents a replicable demonstration pathway for the industry’s green transformation.

In addition, hydrogen energy has become a research hotspot due to its high calorific value (142 MJ/kg, 4-7 times than coal) and zero carbon emission characteristics. Its technical pathways include pure hydrogen combustion, hydrogen-coal co-combustion, and hydrogen-based synthetic fuels. Among them, pure hydrogen combustion needs to solve the problems of flame stability and NOx control, while co-combustion technology (e.g., 5%-10% hydrogen blending ratio) can be used as a transitional scheme to reduce transformation costs. Data from the European Cement Association shows that for every 10% increase in the hydrogen substitution rate, CO₂ emissions per ton of clinker can be reduced by approximately 8%-12% [50]. Companies such as LafargeHolcim and HeidelbergCement have achieved nearly 100% net-zero fuel operation in Europe. In China, BBMG Research Institute has completed an industrial test with 70% hydrogen concentration, and Sinoma international is tackling the technology of co-combustion of hydrogen and alternative fuels, aiming for substitution rate of over 80%. However, the large-scale promotion of hydrogen energy is still restricted by the economic efficiency and infrastructure shortage [51].

In summary, fuel substitution technology provides multiple options for low-carbon development of cement industry, and international application has verified its feasibility and emission reduction potential. Although the current substitution rate in China is relatively low, with technological innovation and system improvement, coupled with breakthroughs in new fuels such as hydrogen energy, fuel substitution technology is expected to play a pivotal role in promoting the green transformation of cement industry and helping achieve decarbonization goals.

3.6 New Energy Technologies

New energy technologies in cement industry, centered on electric calcination and renewable energy (wind power/photovoltaics) combined with energy storage for peak shaving and valley filling, provide clean energy solutions for industry’s low-carbon transformation. Currently, there have been certain application, but bottlenecks such as land constraints and economic viability still exist.

Specifically, electric calcination technology replaces fossil fuels through electromagnetic induction heating, plasma heating, and other methods, which is expected to directly eliminate fuel combustion emissions that account for 40% of cement carbon emissions. However, it is still in the pilot or demonstration stage. The wind-solar-storage integration technology combines photovoltaic, wind power, and energy storage systems. It utilizes idle space in cement plants for photovoltaic power generation, builds wind power generation adjacent to the plant area, and is equipped with large-scale energy storage battery systems. Through intelligent microgrid management, it achieves multi-energy complementarity, which can increase penetration rate of green electricity to 30%-40% [52].

In terms of application status, Heidelberg has actively laid out wind and photovoltaic projects, deployed lithium-ion energy storage systems combined with intelligent microgrid technology to stabilize electricity price fluctuations and improve the utilization rate of green electricity, and actively explored the path of producing hydrogen from wind and photovoltaic power to replace fossil fuels. Cemex adopts hydrogen calcination and electric heating kiln technologies to reduce reliance on fossil fuels, reducing the carbon footprint of some products by 70%. Domestic leading enterprises such as CNBM and Conch Cement have also actively made layouts, as detailed in Table 11. Industry data shows that wind-solar-storage systems can reduce electricity costs by 18-25% and reduce carbon emission intensity by 10-15% [53].

However, this technology faces two major bottlenecks: land resource constraints, as each MW of photovoltaic installed capacity requires 1.2-1.8 hectares of land [54]; and economic constraints, with the investment payback period of projects mostly being 7-9 years [55]. Nevertheless, with the improvement of photovoltaic module efficiency and the reduction of energy storage costs, its application potential will be further released.

In summary, new energy technologies provide an important pathway for the green transformation of cement industry. Despite existing challenges, with technological progress and cost optimization, they are expected to play a key role in the low-carbon development of cement industry.

4 Summary and Outlook

Under the strategic guidance of China’s “dual-carbon” goals, China cement industry has developed a comprehensive value chain innovative carbon reduction system that integrates process innovation, equipment upgrades, new energy adoption, and carbon management. The industry is now at a critical juncture, transitioning toward deep decarbonization and carbon neutrality after the peak CO2 emission reached in 2020, yet it continues to face two major challenges. Technologically, innovation bottlenecks persist—CCUS remains costly, while key areas such as hydrogen safety and co-processing of alternative fuels require further breakthroughs and demonstration. Systematically, policy mechanisms and carbon accounting standards still need strengthening and acceleration.

To achieve the long-term vision of carbon neutrality, China cement sector must pursue strategic advances in both global technological collaboration and domestic industrial transformation. Top-level design should focus on improving carbon pricing, taxation mechanisms, and industry standards. At the industrial ecosystem level, vertical integration and horizontal cooperation should be enhanced to enable coordinated emission reductions across the entire value chain—from raw material extraction to concrete application. Technologically, greater emphasis must be placed on integrated innovation across multiple pathways, overcoming cost barriers in key technologies, and scaling up mature solutions to improve cost-effectiveness.

The journey to carbon neutrality for China’s cement industry is both challenging and promising. It is a complex systemic undertaking that demands cross-sector collaboration, the integration of diverse technological routes, and the joint creation of a circular economic ecosystem and value chain. There are no simple solutions—success will depend on sustained innovation, mutually beneficial partnerships, and the cumulative impact of incremental progress.