Decarbonizing lime kilns with alternative fuels

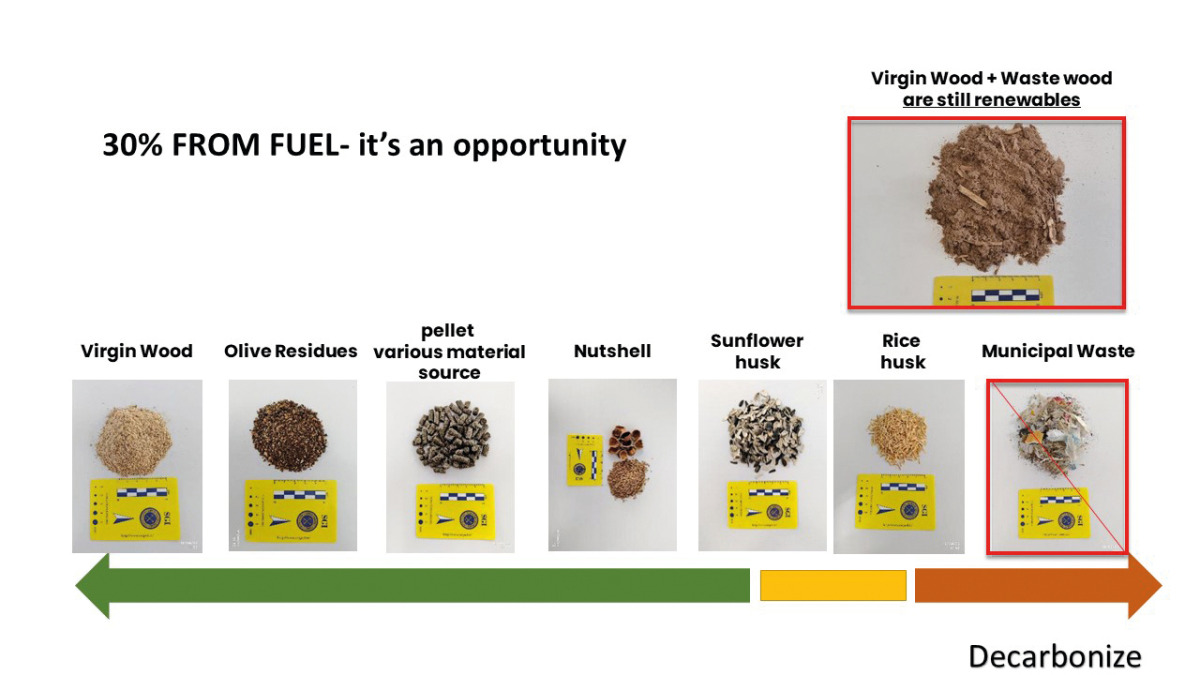

30% of the CO2 emissions are fuel related emissions. While the use of alternative fuels, such as refuse derived fuels is common practice in the cement industry, the use of alternative fuels in the lime industry is still in its early stages. In the following, the opportunities for the use of various types of alternative fuels such as refuse derived fuels in modern lime kilns are summarized.

Lime is a mineral product derived from limestone by an industrial process. Naturally occurring limestone is composed almost exclusively of calcium carbonate. The lime production process is based on a chemical reaction induced by heating calcium carbonate (CaCO3) to produce quicklime (CaO). Inevitably, this reaction also produces CO2. These emissions of CO2, which are inherent to the lime production process, are called process emissions. These process emissions alone constitute 70% of the total CO2 emissions from the lime production process, and they cannot be avoided.

The annual production capacity for lime has increased significantly over the years. In 2013, the worldwide lime production was 350 million t, and it has increased to 430 million t in 2022 [6, 7].

High quality requirements

The lime industry is a highly energy intensive industry with energy accounting for 30-60% of total production costs. Kilns are fired with fossil fuels, such as solid, liquid or gaseous fuels as well as – in a very low level- with refuse derived fuels or biomass. The use of refuse derived fuels (RDF) depends on the expected lime quality, as RDF can have an effect on lime quality. In order to understand the high quality demands placed on the fuels for lime production, it is useful to look at the main applications of the lime produced. Lime is a pure chemical product with >98% active CaO that is used in a wide range of applications, including in the food and pharmaceutical industries. In the following we refer exclusively to quicklime, or so-called ‘burned lime’. Quicklime is calcium oxide (CaO) produced by the decarbonisation of limestone (CaCO3) and represents app. 90% of the produced lime.

To understand the limiting factors for the use of alternative fuels in lime production, it is useful to compare the typical composition of limestone with representative analyses of alternative fuels, such as those used in the German lime industry, and ashes from such alternative fuels.

Due to the areas of application of the various lime products, the use of alternative fuels in lime production is often prohibited, since undesirable impurities, trace elements, etc. are also added to the pure lime product in the form of ash via the fuel. In general, therefore, when using alternative fuels for the lime industry, the ash content should be limited to less than 6–10%, depending on the lime product. For certain applications, e.g. in the food or pharmaceutical industry, the use of waste-derived alternative fuels should therefore be excluded. Further restrictions are to be examined on a case-by-case basis.

Other alternative fuels can have a positive influence on the lime grades produced. For example, the use of meat-and-bone meal as an alternative fuel for lime products was shown to be positive for the fertilizer sector, due to the P2O5 content in meat-and-bone meal.

High demands are also placed on the nitrogen content of alternative fuels. Tests have shown that finely ground woody biomasses contain a nitrogen content of up to 1%. Major constituents in wood are carbon (from 45 to 50% of the mass), followed by oxygen (about 40-50%), hydrogen (about 6%), and nitrogen (up to 1%) [8].

The flue gas temperature at parallel flow regenerative kilns (PFRK) is just above 100 °C, with a Lambda of slightly above 1. In order to reduce the NOx emissions by an SCR System, the flue gases need to be reheated in order to comply with the NOx limit of 350 mg.

Technical requirements for the use of solid alternative fuels in lime kilns

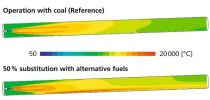

Lime is produced in various kiln types. The heat consumption varies on these different kiln types, so that many lime companies have invested in parallel flow regenerative kilns (PFRK). The use of solid alternative fuels in rotary kilns is well known from the cement industry. Standard refuse derived fuels or solid recovered fuels in a grain size of up to 30 mm without three dimensional parts is fed pneumatically through a dedicated feeding line through the main burner. This is common practice in the lime industry, and most of the more energy intensive rotary lime kilns in Europe are using such alternative fuels. Liquid waste fuels can be used in rotary kilns (LRK, PRK), annular shaft kilns (ASK), parallel flow regenerative kilns (PFRK) and special types of other kilns (OK), e.g. regular shaft kilns with side burner and double-incline kilns.

When solid fuels are pulverised, they can be used in all the above-mentioned types of kilns. Bigger grain sized refuse derived fuels of up to 30 mm can only be used in rotary kilns (LRK, PRK).

Technical requirements in ASK and PFRK kilns

Annular shaft kilns (ASK) and parallel flow regenerative kilns (PFRK) have a different feeding and dosing system for fuels. In such kilns, the fuel is provided to a number of lances in the combustion zones. The lances, typically with a diameter of only 18-30 mm providing the fuel in small quantities of between 30-150 kg per lance/per hour.

A PFRK can have up to 36 lances, arranged as ring line around the kiln. the fuels are provided through a dedicated pneumatic feeding and weighing systems which are pressure surge resistant and able to provide constant and homogenous feeding of pulverized alternative fuels up to 3-5 mm. In ASK, even small alternative fuel pellets of up to 8 mm length and 6 mm diameter can be fed into the upper burners. Such dedicated dosing and feeding systems are provided by a number of companies, such as Carbotech (Germany), Esch (Germany), Maerz (Switzerland) and Schenck Process (Germany).

Fuel physical quality requirements

When using solid alternative fuels in lime plants, specific requirements on the physical parameters are given. Kilns can be either equipped with feeding systems for pellets in a size of max. 8 mm length or fine milled fuels in a grain size of <5 mm. MVW Lechtenberg’s daughter company “Blue River Recycling” produces in its processing facility in the port of Papenburg, Germany dedicated pellets for the lime industry as well as pulverised fuels. With a capacity of more than 100000 t/a, mixed waste is sorted, dried and processed into pellets.

The pellets consist either purely of mixed plastic waste, or mixtures of e.g. up to 75% wood and 25% plastics in order to achieve a minimum calorific value of 21.5 MJ/kg, which is equal to the calorific value of ground lignite, which is currently widely used in the German lime industry.

RED III – CO2 emission reduction while using alternative fuels

Lime production releases CO2 emissions through the calcination of limestone and the use of fossil fuels. The emission factors are shown in the below table. For the process related emissions, the lime industry is currently developing several projects for carbon capture in order to minimize the environmental impact.

Since the introduction of the Renewable Energy Directive (2009/28/EC) in 2009, the deployment of renewables has kept growing yearly, reaching 21.8% in 2021. In July 2021, the

Commission proposed another revision to accelerate the take-up of renewables in the EU and to help reaching the 2030 energy and climate objectives [1].

The ambition and measures in the directive have been reviewed several times in order to deliver the urgent emission cuts (at least 55% by 2030) that are required to achieve the EU’s increased climate ambitions. In July 2021, the Commission proposed a revision of the directive (COM/2021/557 final) with an increased 40% target as part of the package to deliver on the European Green Deal. In May 2022, the Commission proposed in its Communication on the REPowerEU plan (COM/2022/230 final) to further increase this target to 45% by 2030. The Council and the Parliament negotiators reached a provisional political agreement on the 30th of March 2023 to raise the share of renewable energy in the EU’s overall energy consumption to 42.5% by 2030 with an additional 2.5% indicative top up that would allow reaching 45% [2].

On April 18th, the European commission agreed on new emission reduction goals within the “Fit for 55” package. The “Fit for 55” package is a set of proposals to revise and update EU legislation and to put in place new initiatives with the aim of ensuring that EU policies are in line with the climate goals agreed by the Council and the European Parliament [3]. The EU agreed to cut overall CO2 emissions by 2030 at least by 55% compared to 1990. It was further agreed to reduce the free CO2 allocations for the industry step by step and stop free allocations by 2034. This will boost the need for more alternative fuels such as refuse derived fuels or solid recovered fuels with a high biogenic content to enable the lime industry to reduce the fossil CO2 emissions.

By using alternative fuels in the lime industry, the biogenic content (means locally available wood, tree trimmings, but also biogenic parts such as non-recyclable paper and cardboard, textiles etc.) will have a significant influence on the fossil CO2 saving in the lime industry.

In the following, a cost comparison of fossil fuels and RDF pellets as well as wood pellets is shown. The RDF pellets mainly consist of non-recyclable plastics as well as wood. The CO2 price was given with 90 €/t (EU/ETS).

Summary

Lime production is an energy intensive process. The European Lime Association (EuLA) states that the lime industry decarbonisation measures are mainly ‘end-of-pipe’ solutions, such as carbon capture and storage or usage and carbonation, as 68% of the industry’s CO2 emissions are derived from the processing of raw materials. It is estimated that approximately 400 Mt/a of CO2 are released into the atmosphere by the lime industry.

App. 30% of the fossil CO2 emissions are fuel related. By using pelletized or pulverised alternative fuels with a high biogenic content, this could be a “low hanging fruit” to significantly reduce fossil CO2 emissions by using existing and economic technologies.

Other alternative fuels, such as syngas (produced from processed alternative fuels), hydrogen (from renewable energy sources and biogas (from anaerobic digestion plants) can complement a 100% fossil free fuel supply to the lime industry.

![1 Fields of application for lime (Source: EuLA [5])](/uploads/images/2023/w300_h200_x600_y435_GC_Lechtenberg_Figure_1-8190968832903fb3.jpeg)