Digitalization in cement plants: The critical role of accurate inventory data for the industry’s future

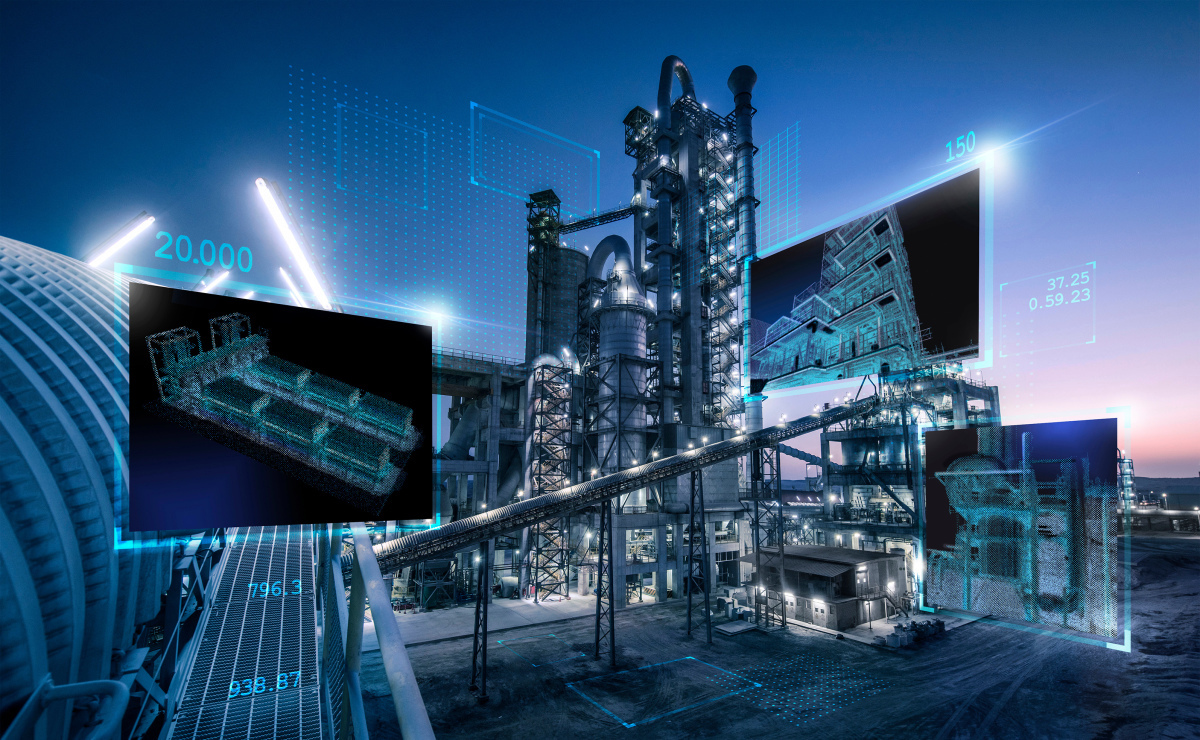

The cement industry — one of the world’s oldest and most energy-intensive sectors — is undergoing a fundamental shift. Digitalization and Industry 4.0 technologies are increasingly shaping production processes and supply chains. As efficiency and sustainability become critical success factors, accurate management of raw material inventories is taking center stage.

Modern digital systems offer a decisive advantage by replacing traditional inventory monitoring methods with precise, data-driven solutions. With the right technologies in place, cement plants can gain full transparency over their material flows, respond faster to changes, and operate more efficiently — both economically and environmentally.

Why inventory accuracy matters in cement operations

Cement production is a highly complex process that depends on the consistent availability and quality of key raw materials such as limestone, clay, and gypsum. A significant portion of production costs is tied to the procurement and storage of these materials. At the same time, plants require a reliable and precisely managed raw material supply to ensure stable thermal and chemical processes in rotary kilns.

However, the industry faces multiple challenges: fluctuations in material quality, pressure to reduce production costs, and increasingly strict environmental regulations. Traditional inventory monitoring methods — based on manual estimations and periodic checks — are no longer sufficient. They often deliver inaccurate data, leading to production disruptions, material shortages, or excessive inventory levels that tie up capital and drive up operational costs.

Digital technologies deliver precision – and real added value

Modern technologies such as LiDAR (Light Detection and Ranging) are bringing a new level of precision to raw material inventory management in the cement industry. By emitting laser pulses, LiDAR sensors continuously scan stockpiles and generate detailed three-dimensional models — with centimeter-level accuracy and millions of data points in real time.

The key benefit: stock levels no longer need to be estimated or checked manually. Instead, reliable, up-to-date data is available at all times, providing a solid foundation for well-informed decisions in day-to-day operations. Whether it’s adjusting inventory levels, streamlining logistics processes, improving storage utilization, or ensuring timely reorders — LiDAR-based insights help make workflows more efficient and responsive.

The data captured can be seamlessly integrated into existing inventory or resource management systems, giving teams full transparency across materials, locations, and production sites. Plant managers and logistics teams gain direct access to accurate, real-time information — wherever it’s needed.

An intuitive dashboard adds additional functionality: it enables visual monitoring of stockpile volumes, supports trend analysis, and allows for automatic alerts when defined thresholds are reached. These notifications can be customized to meet specific operational needs — helping to avoid both material shortages and excess inventory.

Even distributed or remote sites can be monitored centrally. With mobile access via smartphone or tablet, inventory control becomes not only more precise, but also more flexible — supporting faster decisions and better planning in a dynamic production environment.

Sustainability and economic Impact

Accurate inventory data contributes not only to operational efficiency but also to greater sustainability in cement production. Given that the industry is responsible for around 8% of global CO₂ emissions, every improvement counts. With optimized logistics planning, transport routes can be streamlined, reducing both transportation costs and emissions. Precise inventory control also helps minimize material waste and ensures consistent product quality.

Reliable data improves planning certainty across the board. Production can be better aligned with actual demand, reducing the risk of overproduction and the associated costs — while supporting more flexible, efficient operations.

Digital transformation as a strategic advantage

Digitalization is more than just a response to current challenges — it’s a strategic investment in the future of the industry. Stricter environmental requirements and rising expectations around resource efficiency will continue to shape the sector. By implementing technologies like LiDAR sensors and integrated inventory systems at an early stage, cement producers can position themselves to meet these demands head-on.

Innovative technologies are fundamentally changing how cement is produced and managed. Companies that invest in digital transformation today are not only strengthening their current market position — they’re also building the flexibility needed to stay competitive in the years ahead.

A key to efficiency and sustainability

Digitalization opens up new potential for boosting efficiency, reducing operating costs, and increasing sustainability in the cement industry. Accurate inventory data plays a crucial role in this transformation — providing the foundation for better decisions and more streamlined processes. With technologies such as LiDAR, cement plants can address current challenges with confidence and prepare effectively for what’s next in an evolving industry.