FGD gypsum can largely be replaced by gypsum and anhydrite stone

A current study by the Federal Institute for Geosciences and Natural Resources (BGR) initially shows bottlenecks in the supply of gypsum raw materials.

For some time now, manufacturers’ associations have been pointing out that the phasing out of coal-fired power generation could lead to a shortfall in the supply of gypsum raw materials. The potential of gypsum recycling is currently insufficient and cannot be fully exploited due to the lack of a legal basis.

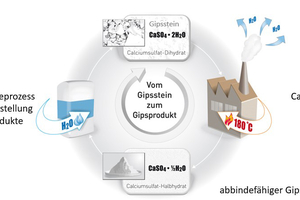

Will there be a shortage of gypsum in Germany if coal-fired power plants are no longer connected to the grid? “Yes,” says a BGR study, which has now been presented to representatives from industry, environmental associations and specialist authorities at an industry workshop organized by the German Mineral Resources Agency (DERA), which is part of the BGR, and warns: “The domestic supply of gypsum raw materials is threatened by bottlenecks.” Study author Sören Henning cites the planned coal phase-out by 2038 as the reason for this, which means that this important source of raw materials for the building materials industry will no longer be available. Currently, around 50% of the gypsum processed in the building materials industry comes from flue gas desulphurization plants (FGD gypsum) in coal-fired power plants.

According to the BGR raw materials expert, the use of natural resources is a conceivable solution. However, complex and lengthy approval procedures make it difficult to access the abundant deposits available in Germany. Alternative sources of gypsum are not entirely suitable for use in the construction industry.

The Bundesverband der Gipsindustrie e.V. (Federal Association of the Gypsum Industry) has a similar view of the situation. “The difficult economic environment in the construction industry and the fact that the number of building permits fell to its lowest level since 2010 last year should not obscure the fact that demand for gypsum building materials remains high,” predicts Dipl-Ing Holger Ortleb, Managing Director of the Federal Association of the Gypsum Industry and the Research Association of the Gypsum Industry. In this context, Ortleb refers to the need to create new and affordable living space. According to a study conducted by the German Economic Institute (IW) last fall, 372600 new homes would have to be built nationwide each year to meet demand. “With building materials made from gypsum, modern living space that meets demand can be created in the shortest possible time at a reasonable cost,” emphasizes Holger Ortleb. “In existing buildings, high-performance dry construction solutions can make an important contribution to meeting demand promptly, quickly and efficiently.”

But where will the building material come from in the near future when the last coal-fired power plant goes offline and the extraction of natural gypsum deposits is increasingly restricted for reasons of local acceptance or lengthy planning and approval procedures? “Gypsum recycling can play an important role in the national supply of raw materials in the future,” says Holger Ortleb. “This building material in particular is ideally suited for this because it can be recovered almost unmixed and recycled again and again in high-quality cycles,” Ortleb continues.

Since the presentation of the gypsum industry‘s recycling concept in 2014, the amount of recycled gypsum has been increasing year on year. The statistics for 2023 show an increase of 17% compared to the previous year. However, this should not obscure the fact that the volume of recycled gypsum is nowhere near enough to cover the demand for raw materials. “Recycling is making a growing contribution to the gypsum supply. However, even in the long term, the quantity produced is not sufficient to fully compensate for the loss of FGD gypsum,” emphasizes BGR expert Sören Henning. The German Gypsum Association takes a similar view and is therefore calling for a legal basis to be created as quickly as possible to ensure the timely use of natural gypsum. “In order to be able to make optimum use of the potential of gypsum recycling, it is urgently necessary for politicians to remove existing obstacles and create the necessary legal certainty for the use of recycled gypsum,” demands Holger Ortleb. To this end, DERA recently published a position paper with recommendations for action as part of the Recycling Raw Materials Dialogue Platform, which can be accessed via this link:

The BGR study “Gypsum and anhydrite” is available for download at this link: https://www.bgr.bund.de/DE/Themen/Min_rohstoffe/Downloads/rohsit-2023.html