Fire protection and circular economy: Opportunities and hurdles using the example of drywall constructions

Circular economy in the construction industry: Approaches and opportunities

Drywall constructions are excellently suited for the purpose of structural fire protection. Structures ranging from non-load-bearing internal partition walls to suspended ceilings and shaft walls have been certified for their fire resistance capability, either by inclusion in DIN 4102-4 or through manufacturer-specific certificates such as abP (general building authority test certificates), abG (general type approvals) or ETA (European Technical Assessment). In addition, drywall constructions are ideal for the requirements of the circular economy thanks to their design principle, in which various components form a highly effective overall construction.

Principles of the circular economy

The aim of circular economy in the construction industry is to extend the life cycle of building components and materials and to keep them in circulation for as long as possible. In this way, primary raw materials can be conserved and wastage of construction material can be minimised. Assessment of construction materials or components with regard to their suitability for the circular economy is based on the amount of processing required and the level of a possible subsequent utilisation.

The top priority is to avoid waste by conserving or repairing a building component. If this is not possible, then construction materials legally become waste when they are dismantled or demolished. Here, too, there is a clear hierarchy:

Most favourably rated are construction products and materials that can be reused after preparation (preparing for re-use). This can apply, for example, to built-in parts or components of a structure.

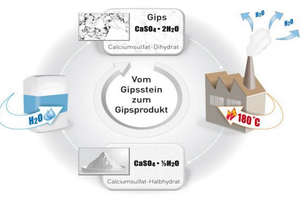

The second highest rating is given to recycling, in which a construction material is reprocessed and utilised as a raw material for a product of equal or higher value. This is the case for example with gypsum recycling, where the recycled construction material is returned to production as a secondary raw material. This closed material cycle is known as ‘closed-loop recycling’.

Less favourably rated is the use of a construction product or the ingredients of a construction product for a less qualified application (recovery). In addition to ‘downcycling’, this also includes backfilling (material recovery) and thermal utilisation (energy recovery).

If none of these three options are possible, then construction materials or construction products are permanently removed from the cycle as waste products and must be disposed of (disposal).

From a legal point of view, dismantled or demolished construction materials or construction components are initially considered to be waste. The conditions for the utilisation of raw materials without waste status for the manufacture of new construction products are defined in Section 5 paragraph 1 of the Act to Promote the Circular Economy and Ensure the Environmentally Sound Management of Waste (Kreislaufwirtschaftsgesetz - KrWG):

1. The characterisation of a substance or object as waste ends when it has undergone a recycling or other recovery process and is of such a nature that 1. it is normally used for specific purposes,

2. there is a market for it or a demand for it, 3. it fulfils all technical requirements applicable to its respective intended purpose as well as all legal provisions and applicable standards for products, and

4. its overall utilisation does not result in harmful effects on human beings or the environment.”

For this reason, planners and building owners should in future ensure that they favour construction materials that can be kept in circulation at the end of the building‘s life cycle. Drywall constructions offer all the necessary prerequisites for fulfilling this requirement.

Drywall constructions: Components and demolition

Drywall constructions are created by the professional assembly of various construction materials, such as metal profiles, mineral wool insulation materials and plasterboard, to form highly effective, tried and proven components. This creates a wide variety of systems, which is particularly necessary with regard to fire protection and sound insulation. Common components of drywall constructions can be assessed favourably in terms of their suitability for the circular economy, as they enable material recycling when separated by type:

Gypsum or gypsum fibre boards are ideal for the circular economy. Gypsum is the only natural mineral material that can be recycled in a closed cycle and used again and again as a secondary raw material for gypsum products (closed-loop recycling). Proven processes and defined quality standards ensure the production of high-quality recycled gypsum and the conservation of valuable primary raw materials.

The metal substructure can be recycled as steel scrap and used as a secondary raw material for new steel products.

Mineral wool insulation materials, which are frequently used in fire protection constructions, can be kept in circulation and recycled into new insulation materials.

The decisive factors for suitability for the circular economy are careful dismantling and demolition to avoid cross-contamination and the separation and collection of construction materials by type. The legal basis is the “Ordinance on the Management of Commercial Municipal Waste and Certain Construction and Demolition Wastes 1 (Commercial Waste Ordinance - GewAbfV)”. Its section 8 requires many construction materials, including gypsum-based construction materials, to be „collected and transported separately and ... prioritised for preparation for reuse or recycling“.

The concept of material recycling is being intensively pursued by manufacturers and implemented wherever possible. In the case of drywall constructions, the dismantling and preparation for re-use of plasterboard and components of the substructure is theoretically also a promising concept. However, it involves product and building law issues which are difficult to solve or can only be solved by highly competent market participants.

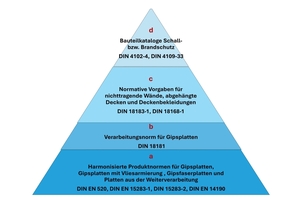

Dry construction with plasterboard: A construction method comprehensively described in standards

One hurdle for the re-use of gypsum plasterboards is the description of all aspects of drywall constructions that are relevant to building law in a ‘standardisation pyramid’, which is based on harmonised product standards (level a) upon which the other standards (level b-d) are established. This enables clear statements to be made about the quality of gypsum plasterboards as products as well as statements about the drywall systems constructed with them and the properties of these systems.

The gypsum plasterboards are standardised (DIN EN 520 or DIN EN 15283-1/-2) and processed in accordance with standards (DIN 18181), and are generally part of standardised components or structures (DIN 18183-1 or DIN 18168-1), which means that the structural stability of the structures is deemed to have been verified.

The classification and building-law-relevant allocation of the structural-physical properties of selected constructions using plasterboard can be found in the standards described as ‘component catalogues’, such as DIN 4102-4 for fire protection or DIN 4109-33 for sound insulation.

In this way, conventional drywall constructions are consistently described in standards from the product level, through processing and the description of associated constructions, right up to the structural-physical properties of the components.

Particularly for use in structural fire protection, there are many classified building structures available in dry construction which are either certified by DIN 4102-4 or by manufacturers‘ usability certificates (abP, abG, abZ, ETA). Almost all certificates make reference to the aforementioned standards and thus stipulate the mandatory use of precisely defined products, processing methods and constructions.

In the case of gypsum plasterboards that are not covered by the above-mentioned standards, there are no standardised verifications for the stability or the physical properties of the structures built with them.

The complex verification procedures via abP, abZ, aBg or ETA are of course open to a “manufacturer or distributor” of such plasterboard products. However, this also requires a clear definition, labelling and proof of guaranteed properties of the board material used.

From waste to product status: Three approaches for re-use plasterboards

When plasterboard construction materials are reused, the status of the material concerned must be clarified, because plasterboard that is removed for reuse thereupon loses its product status and the validity of its CE labelling: it is legally then classified as waste. In order to end the material‘s classification as waste, the processors or distributors must follow one of three approaches and fulfil the criteria of the Closed Substance Cycle Waste Management Act, namely: meaningful utilisation, existence of demand, compliance with technical requirements and proof of non-harmfulness to health and the environment.

Meaningful applications are available to varying degrees depending on the approach. Demand is determined by the price-performance and cost-benefit ratios. These topics will not be further addressed here. Instead, this section considers the extent to which proof of the technical requirements for the respective approach must and can be provided:

Approach 1: Integration of the re-use plasterboard into the existing standardisation framework

The reprocessed and newly declared re-use plasterboards could be used in all areas of application and constructions that are governed by particular standards. For this purpose, three questions must be answered positively:

1. Can the product properties required by the standards be achieved again through reprocessing?

2. Can proof be provided that the re-use plasterboards are in conformity with the standards?

3. How and by whom will the new CE certification be carried out?

Approach 2: Re-use gypsum plasterboard or a product made from it with deviating properties and individual certificates of suitability and usability

If a processor wants to launch its own construction product with defined criteria onto the market, individual certificates of suitability and usability are required. This is an option for well-informed, economically strong market participants, but it is not a solution for the general market.

Approach 3: Re-use plasterboard for subordinate applications not relevant to building regulations

A re-use product with reduced defined and proven properties for subordinate uses that are not relevant under building law is no longer deemed a construction product within the meaning of the EU Construction Products Regulation (CPR), Art. 2. 1 and is not considered here. At this point, only Approach 1 will be analysed further, as it is the only approach that enables the large-scale utilisation of re-use plasterboard in drywall and timber construction.

Demolition or dismantling of gypsum plasterboards

Theoretically, plasterboard can be demolished or dismantled in two ways:

For material recycling, mechanical fragmentation into small pieces is a common method. In this process, the original structure of the board is completely or partially destroyed.

Cutting out plasterboard sections between the stanchions or undoing the screw connections are dismantling methods that can be used before reprocessing for re-use. In the first option, the dimensions and edge configuration are changed; in the second option, the structure that has been weakened by screw holes must be restored during the reprocessing.

Firstly, the question arises as to which plasterboard types according to DIN EN 520 are available as source material, and what conditions the plasterboards have been exposed to during the service life of the component.

It is always possible that the strength of the plasterboards could have changed due to stress occurring during installation, dismantling and further processing.

Under these preconditions, proof of conformity in accordance with DIN EN 520 has to be provided for the recycled plasterboards. However, due to the different source materials obtained from demolition, it is questionable whether this is legally possible in a reliable manner. The associated issues can be resolved by qualified processors exercising a great deal of care and effort or by restricting themselves to clearly defined source materials.

Normative requirements for plasterboards and proof of conformity

The standardised requirements which have to be met, declared and verified for processed plasterboards is explained here using the example of plasterboards conforming to the harmonised DIN EN 520 standard. This standard specifies the requirements concerning the characteristics, geometry, strength, structural-physical properties and the emission of hazardous substances and contains requirements for test methods, conformity assessments, marking and labelling.

When re-use plasterboards are processed professionally, the length, width and rectangularity requirements are easy to fulfil, regardless of the method of dismantling. However, this is different in the case of the required wrapping of the longitudinal edges. This wrapping has to be subsequently re-applied if the boards are cut out of structures during dismantling.

However, it is more difficult to provide the required proof of conformity for re-use plasterboards with respect to flexural strength, structural cohesion in the case of type F plasterboards, and - where applicable - the emission of hazardous substances. The reason for this is the inhomogeneity of the source material, which can differ in terms of the type of board, the handling during installation and dismantling and the treatment or surface coating during its service life. It is therefore questionable whether type tests, such as those required by DIN EN 520 for plasterboard, can be carried out in a meaningful way for a re-use product type. Without these type tests, however, it is not permissible to label the product, place it on the market as a construction product or use it in areas of application relevant to building law.

Recycling: The solution of choice for drywall construction

The re-use of gypsum plasterboard and gypsum fibreboard after reprocessing will initially remain a niche solution due to the narrow normative and product law framework for constructions governed by building law requirements. The solution of choice is material recycling: it is tried and tested, economical, substitutes for valuable primary raw materials and serves as the basis for new construction products with the same level of performance.

Deutsche Fassung EN 14190:2014

Deutsche Fassung EN 15283-1:2008+A1:2009

Deutsche Fassung EN 15283-2:2008+A1:2009

Baustoffe, Bauteile und Sonderbauteile

- Holz-, Leicht- und Trockenbau