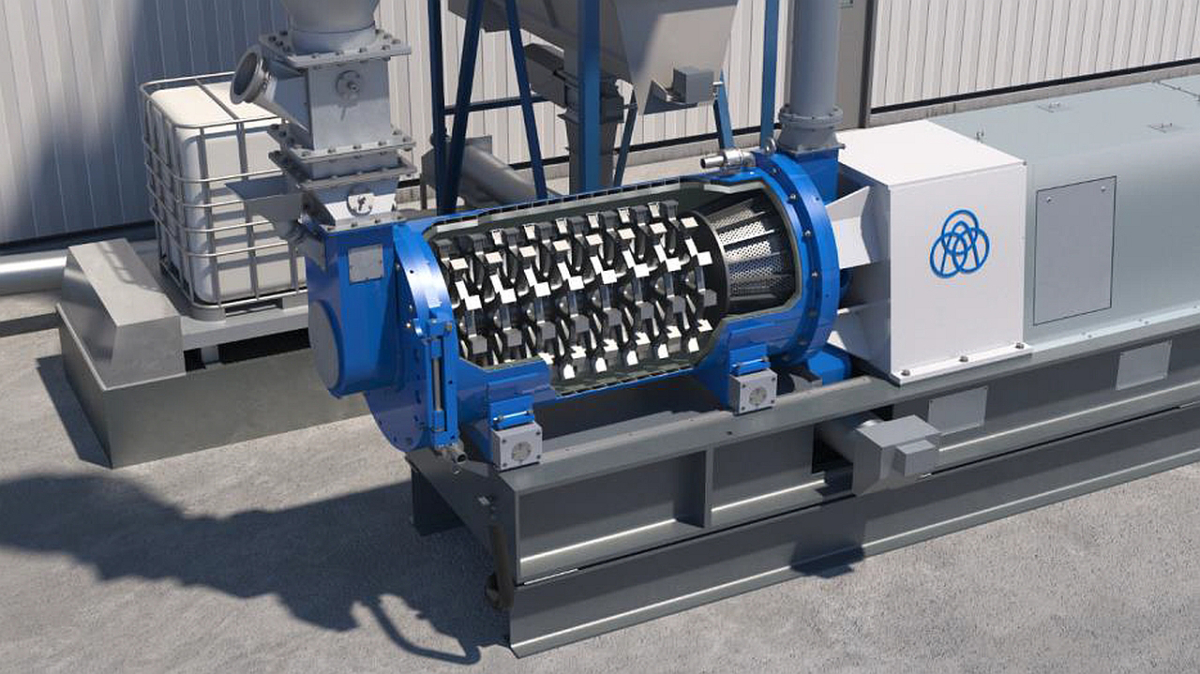

First industrial reference for a polysius booster mill to reduce clinker factor

To reduce the clinker factor of cement produced in its plant of Ouagadougou/Burkina Faso, Ciments d’Afrique (CIMAF) has entrusted thyssenkrupp Industrial Solutions AG, BU Polysius, to install a polysius® booster mill. By boosting the fineness and reactivity of the clinker portion, the high energy density mill will enable clinker substitution by local filler while maintaining both cement quality to local standards and production capacity of the exiting ball mill.

Mohamed Naciri, Regional General Manager, Ciments de l’Afrique: “Burkina Faso is a landlocked country where clinker has to travel at least 1200 km to reach Ouagadougou, every technology aiming to decrease the cement clinker factor is welcome, this project is also an important milestone in our decarbonation road map, tkIS is a key partner for CIMAF to decrease our group CO2 footprint.”

Luc Rudowski, Head of Innovation, thyssenkrupp Industrial Solutions AG – BU Polysius: “This first industrial reference for clinker factor reduction with polysius booster mill technology cannot be overestimated; it is accelerating the transition of cement production from #grey2green, aiming to set a new future fine-grinding technology standard in the industry. With CIMAF, we are proud to be partnering, one more time, with an industry entrepreneur showing the right determination and ingenuity to make this happen. Coincidentally, clinker production costs from plants with CO2 capture is expected to be as high as the import costs of clinker in certain West African countries. We are eager to demonstrate the impact of the polysius booster mill as one of our #grey2green solutions to boost clinker potential while reducing it in cement, in a carbon neutrality perspective.”

CIMAF owns and operates 13 grinding plants in ten African countries: Burkina Faso, Cameroon, Chad, Ivory Coast, Gabon, Ghana, Guinea Bissau, Guinea, Mali, and Mauritania. CIMAF’s parent company, OIP, is a major cement supplier across north, west, and central Africa, producing about twelve million tons annually, and is the third largest cement producer in Morocco with two integrated plants that use wind energy to meet the bulk of their electricity demand.

The advantages of the polysius booster mill:

Reduction of the clinker factor

Boost of cement and Supplementary Cementitious Materials fineness and reactivity

Low Capex boost of production capacity of existing grinding plant

Modular design and small footprint enable integration in existing grinding plants